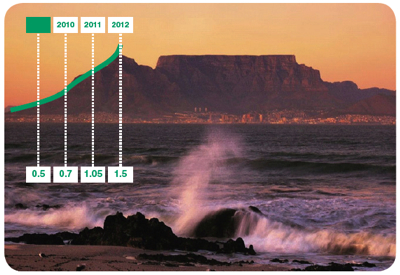

The cost of electrical energy in South Africa has risen very significantly over the past 4 years and is projected to continue rising for the immediate future. EECO2 was called upon by a global pharmaceutical manufacturer to their Tablet Manufacturing Suite facility in Cape Town, South Africa to assist them reduce energy demand without compromising on product quality or regulatory compliance.

The EECO2 solution:

- Install a fresh air cooling coil to eliminate dehumidification within the air handling unit (AHU)

- Rebalance the areas dust extraction system to eliminate nozzles no longer required

- Install a VSD onto the dust extraction unit to maintain pipework carrier velocity

- Consequently enabling a reduced fresh air volume

- Rebalance the Air Change Rates to reflect area manufacturing change of use

- Initiate non-operational air volume reductions

- Optimise BMS system

Product risk elimination:

- From the project’s inception risk elimination was the team’s core focus

- Product risk assessments were developed with the site QA, production & engineering team

- Risk mitigation was evaluated and included where required

- Final design changes reflected a risk adverse approach.

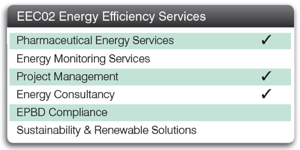

Off site support: EECO2 supported HVAC design, product risk assessment, on site commissioning Luwa provided the local engineering & technical support to deliver the implementation .

The unique challenges:

The Tablet Manufacturing Suite presented some unique challenges for the team. The global pharmaceutical manufacturer’s products and manufacturing techniques have developed rapidly over the years but the HVAC system in this facility in Cape Town, South Africa was largely the same as originally designed some 15 years ago.

- High volumes of fresh air requiring dehumidification in very challenging ambient conditions

- Adapting the HVAC system to meet current manufacturing requirements

- Reducing the volume of the dust extraction system and install VSD

- Initiating none operational setbacks

- All without impacting on product quality or manufacturing output

In addition to supplying conditioned air to the manufacturing area, the HVAC system also had to dehumidify large volumes of fresh air to provide for personnel, pressure cascades and dust extraction requirements.