Profile

In addition to manufacturing and installation of Air Handling Units, Termovent’s production range includes design, production and installation of a modular panel system used in the field of cleanroom technology (GMP classes A, B, C and D). Not only does our production capacity speak volumes about our company, but also do the references we have acquired so far working with partners such as: Pfizer, Evalar, Hotel Hilton in Belgrade etc.

Main products of company Termovent are: manufacturing of Air Handling Units (HVAC equipment), Clean Rooms and service Engineering.

Air Handling Units

Widespread experience in manufacturing and designing HVAC equipment resulted in range of products created to successfully address various air conditioning, ventilation and air distribution problems.

Termovent Air Handling Units can cover various air flow rates ranging from 800 to 100,000 m3/h. The Air Handling Units can be produced in more than 30 standardized sizes, with high levels of customization to satisfy customer requirements and project specifics.

Some of the references for the Air Handling Units division are: Hotel Gorski, Serum Institute of India, SC Big Novi Sad, etc.

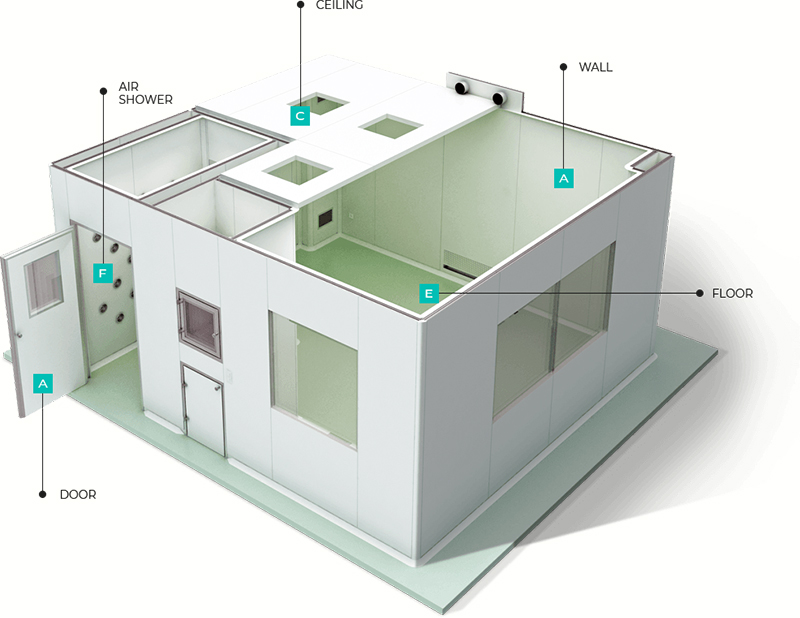

Clean Room

Clean Room is an environment that has a controlled level of contamination that is specified by the number of particles per cubic meter for the appropriate particle size.

Termovent modular CleanRooms system design enables its easy integration with other systems. A combination of various materials offers a wide range of applications: pharmaceutical, micro-electronics industry, chemical and food industry, healthcare institutions, laboratories, etc…

The entire system conforms to the GMP, FDA as well as the ISO 14644 standard guidelines. Compliance with the regulations in the field of the Clean Room Technology enables its use in spaces ranging from class ISO 9 to ISO 1 (GMP classes A, B, C, and D).

Some of references for Clean Room division are: Pharmasyntez, Grand Medic, Evalar…

Engineering

Thanks to the main focus on clean room environment and technology, today TERMOVENT ENGINEERING is able to provide a complete solution to the clients including design, installation works, own software and validation package, from idea to qualified system, all in accordance with GMP regulations / ISO 14644-1 standard, technologies and processes.

With great knowledge and experience, as well as high level of quality and reliability of HVAC (Heating, Ventilation, Air Conditioning), BMS (Building Management System) and EMS (Environmental Monitoring System) systems as well as qualification package in demanding GMP/ISO clean room classes, TERMOVENT ENGINEERING is a strategic and trustworthy supplier to companies that base their business in clean rooms zones.

With a great reference list, good ratio of prices and quality, with own sources as well as responsible specialists dedicated to quality and success of the project, TERMOVENT ENGINEERING doesn’t have an unsatisfied client today. Based on that trust, previous clients are returning, and we are gaining new ones.

TERMOVENT ENGINEERING Clients are Pharmaceutical companies, Healthcare institutions, Microelectronics industries, Battery production, but also Engineering companies.

Some of references for Engineering division are: Pfizer, Zoetis, Purna Pharmaceuticals etc.

CERTIFICATES AS THE GUARANTEE OF QUALITY

As Termovent is fully committed to meet the clients’ requirements in terms of quality, environmental protection, and safety, we set high quality standards that represent the cornerstone of our operations. For achieving set goals, our employees continuously participate in the process of improvement and optimization of the products and services. The success of this approach is confirmed by numerous certificates held by Termovent, which guarantees the highest standards for our customers.

Eurovent Certita Certification has certified that Termovent Air Handling Units, Range KK, and Software for calculation of performances SELECT:pro, Trade name TERMOVENT, have been assessed according to requirements of the following standard: OM-5-2017. Termovent Air handling Units hold CE Marking of Conformity to Machinery Directive 2006|42|EC Annex II, Point A. In addition, Termovent AHUs are designed and produced according to set of harmonized standards: EN ISO 12100:2010, EN ISO 12100:2010, EN ISO 13850:2015, EN 1037:1995+ A1:2008, EN ISO 14120:2015, EN 60204–1:2006/A1:2009 and EN 61000-6-2:2005/AC:2005