Chemistry labs have traditionally been demanding in their need for energy and natural resources, and heavy in terms of their impact on the environment.

Extraction of potentially toxic fumes resulting from experimental work in fume cupboards is generally an energy intensive process and re-purification of chemically contaminated water can create a huge cost burden.

Rising costs and environmental concerns, however, have led to a push for not only greener chemistry in the lab but also more sustainable laboratory designs.

The GlaxoSmithKline Carbon Neutral Laboratory for Sustainable Chemistry at the University of Nottingham Innovation Park is the latest in a line of research facilities looking to be environmentally benign while fostering an outstanding research environment for students.

The laboratory, on Nottingham’s Jubilee Campus, was constructed in partnership with the Higher Education Funding Council for England (HEFCE) and ‘Impact: The Nottingham Campaign’, the University’s largest ever fundraising appeal to change lives, tackle global issues and shape the future.

The Campaign facilitated a £12m grant from global pharmaceutical company GSK as part of its greener chemistry commitment, announced in 2010.

Sustainability challenge

Mark Adey, Director Architect and Rick Sharp, Executive Associate/Project Architect, at The Fairhursts Design Group, explained to S-Lab delegates that GSK was keen to investigate whether it was possible to operate a carbon neutral laboratory building and whether a suitable design could actually be built.

For the carbon neutral concept to be achieved, the building needed to make no overall contribution to greenhouse gases or the acceleration of climate change throughout the entire carbon footprint of the design – from offsite procurement, site construction, occupation and to eventual demolition.

It therefore needed to be carbon neutral throughout the next 25 years of use.

This required a low carbon construction using natural and renewable materials, involving carbon analysis of each element, prefabrication where ever possible, and minimised use of transport.

In terms of energy the build needed to use renewable resources such as photo voltaics (PVs), and biofuel-based CHP to generate more power than it consumes.

In fact, the new chemistry lab has indeed been built from natural materials and is run on renewable resources and the excess energy created by the building will provide enough carbon credits over 25 years to pay back the carbon used in its construction. Some of the heat is also being used to heat the nearby office development on campus.

Materials of choice

The carbon neutral target of the building required careful consideration of each and every element of the building and its construction. From the selection of local and reclaimed materials to the use of off-site manufacturing, every effort was made to ensure waste was minimised throughout construction.

This involved using Vibro stone columns to form the foundation piles; while ground granulated blast furnace slag (GGBS) was used as a cement substitute for the ground floor slab.

The glulam (glued laminated timber) structure required 1,396 tonnes of managed alpine spruce – an area equivalent to roughly two rugby pitches.

Insulation for the walls and roof was provided by woodfibre. The internal walls and external finishes were made in timber stud or solid cross laminated timber (CLT) and once-fired terracotta cladding. Low VOC paints and finishes were used, along with natural rubber floor finishes.

Other specifications were low water consumption fittings, including waterless urinals, LED lighting throughout and underfloor heating.

The building occupies 4500 square meters over two floors and in addition to laboratory space for 100 researchers, it contains dedicated instrument rooms, a teaching lab for advanced undergraduate classes and space for a range of outreach activities.

Unusual floor plan

Matthew Butler, Associate Director, Aecom, reviewed the laboratory’s design brief, which required: naturally ventilated open plan laboratory and write up areas, separate write-up areas, separate areas for hazardous work using mechanically ventilated equipment, and mechanically ventilated laboratories on the first floor.

The final horse-shoe design of the building enabled this to be achieved.

All three of the facility’s NMR machines have been placed in one room and there are no fume cupboards in the general labs: thus only those rooms with heat generating equipment require cooling.

There is a separate ventilation system for each laboratory and fume cupboards can be ‘off’ when not required. Energy use was further reduced in some labs by use of ventilated enclosures with motorised shut-off, and by having a chemical storage cupboard with a separate extract system.

Low energy fume cupboards were used that provide a low face velocity, VAV airflow control and auto sash closing.

Suspended timber service booms incorporate lighting. The labs are also fitted with a chilled, recirculating water system so that condenser water does not have to be taken from the mains supply.

The design includes double-glazed curtain walling to let in maximum daylight. Thus, in contrast to cold and dark labs of the past, the wooden structure produces an airy, light environment without echoes.

LED-dimmable lights react to light, turning up when light is low, while particle detection sensing devices in the roof space warn of heat or smoke in the case of a fire or burning.

Externally, the roof is planted with a wild flower blanket on the north side, while on the south side photo voltaic cells provide energy that is exchanged for carbon credits.

The building also makes use of air- and ground-source heating, while a manmade lake acts as a heat sink.

The biomass boiler, supplied by Fleetsolve, uses a proprietary waste product as a biofuel source, so that no petroleum products are used.

Natural ventilation with heat recovery

Natural ventilation

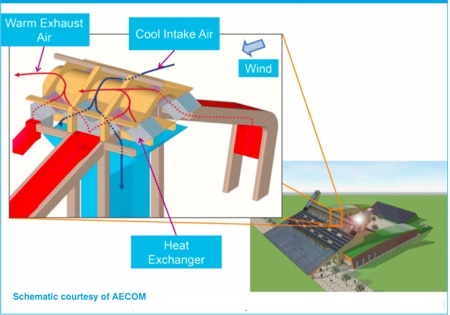

The design of the building makes use of the prevailing wind to assist in ventilating fume hoods in the laboratories, cutting the amount of energy required to extract gases.

This ventilation for the building is achieved through the use of roof-mounted ventilation cowls while fumes are extracted through the feature timber-clad chimneys which were lifted into place as single elements.

Weather stations on the roof feed into the BIM system and the complex shape of extract chimneys speeds the flow of air and prevents eddies above the vents.

One Ventaxia fan drives the air for 10 fume cupboards rather than having a fan for each. It is constantly powering up and down depending on conditions.

The structure is designed to offer maximum ability to change or redesign lab spaces in a matter of hours, and the absence of ceilings in some labs not only provides light airy space but also means all pipework is readily accessed, making maintenance easy.

The ground-breaking building achieved a BREEAM Outstanding rating – this requires a score of 85 or more and puts the building in the top 1-2% of buildings constructed.

It also achieved LEED ‘Platinum’ rating, (the US-based system), which requires a points score above 80.

The lab is unique in the level of detail and effort put into its sustainable design; its existence is even more of an achievement, taking into account that the initial attempt was razed to the ground in a fire.

Peter Licence, Professor of Chemistry at the School of Chemistry and Director of the CNL facility, said: ‘It is amazing to think that our construction team, led by Morgan Sindall, had to start again from scratch under a year ago. The intensity of the blaze meant that everything, including the foundations, had to be rebuilt.’