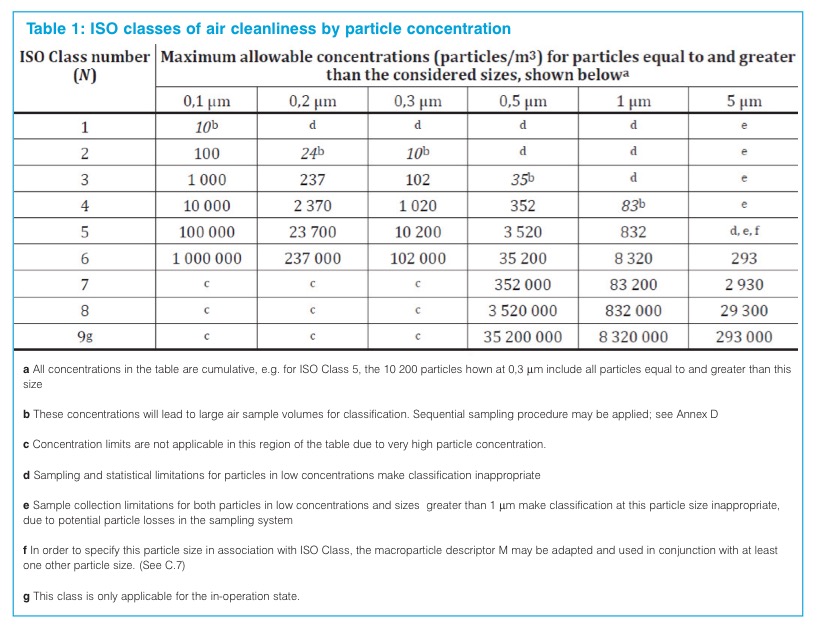

1. Check number of particles allowed for related cleanroom class

No more calculations to determine the maximum allowable concentrations (particles/m3) for particles equal to and greater than the considered sizes. Now, there is a table for this. Table 1 is the only reference for all sizes of particle from ISO 1 to ISO 9.

2. Beware of changes in Table 1

In ISO classes 1, 2, 3 and 5, the particle diameter that could be taken as a reference has been changed. Worth noting is that the limit, defined as 29 particles for 5 μm, does not exist anymore.What is to be done for 5.0 μm in ISO class 5? It seems that the pharmaceutical industry will be affected by this change according to GMP Appendix 1, but there is no need to worry; the 0.5 and 1 μm particle diameters while preparing reports comply with 14644-1 and will be used for ISO Class 5. Besides, by using the M descriptor, it will indicate if the 5 μm value used for making the report is consonant with GMP Appendix 1.

What is the M descriptor?

The new ISO 14644-1 describes M for microparticles the limits of which are not stated on the table. In this case, we will keep on counting 5 μm particles and while documenting the results, it will be indicated as: ISO 5 (20;≥5.0); At rest/Operational; light scattered airborne particle counter (LSAPC). The LSAPC description shows the method used for making this count.With at rest and operational choices, the information on whether the counting is done in stationary or operational conditions can be given. With an M descriptor, it will be recorded whether the value in 5 μm is within the limits of GMP Appendix 1.

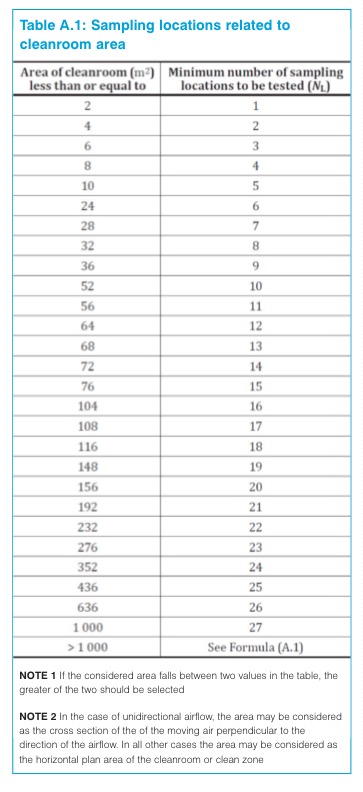

3. Check table A.1 for minimum sample locations

Now there is Table A.1 for the minimum number of sample locations. Get a copy of this table and pin it to your board!4. No more UCL %95 calculations

Good news! You do not need to make an upper confidence limit calculation for counting between 1-9 locations with extra statistical calculations anymore. You just need to do the counting.

The upper confidence limit (UCL) calculation was in the 1999 cleanroom standard edition to keep us on the safe side with statistical calculations. However, if you are considering groups of data in mathematics, larger and smaller numbers have the same impact on the average, standard deviation and mean calculations.

For particle counting, smaller numbers are not the equivalent of larger numbers, because small numbers are good indications of cleaner zones.

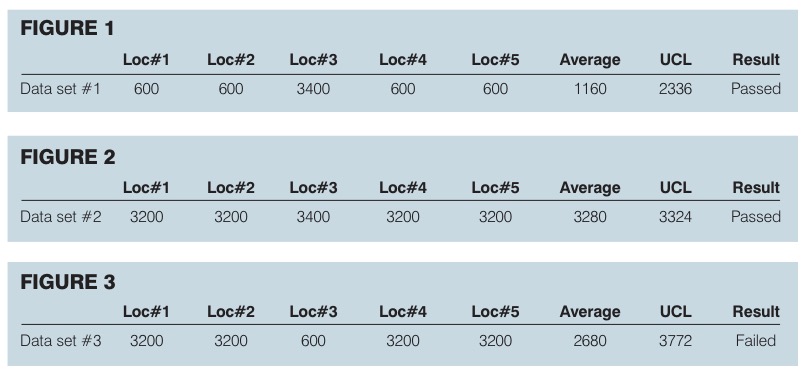

For example, assume you are collecting data in four locations for ISO Class 5, 0.5 μm. As per table 1, your limit is 3520 particles/m3. As shown in figure 1, 3400 particles/m3 in location #3 is very close to the limit and the UCL calculation here is incredibly useful. The result was 2336, which was more than double that of an average calculation. This value is fine because it is still below the limit. This is what we expect from a UCL calculation.

If you look at the second data set, figure 2, on the surface you could say we are facing “a dirtier” cleanroom. However, from a statistical standpoint, this data set has a lower standard deviation. So the UCL for each data set is quite similar with a lower average value. Again the cleanroom passed.

If you compare the third data set, figure 3, with second one, you could say because location #3 is cleaner (3400 to 600 particles/m3) we expect this cleanroom to be cleaner. However, the UCL calculation shows the number 600 is an odd one and the data set ends up with a higher standard deviation. This results in a higher UCL calculation and the cleanroom fails even though here is a better data set.

Just because of this “surprise” and unpredictable result, most of the certifiers were collecting a minimum of 10 data locations (even when they needed 4-5 locations) so that they could predict results onsite before calculating the UCL.

5. The calibration should be based upon ISO 21501-4

It is not specified as the only way to carry it out, but it is suggested that the calibration should be done according to ISO 21501-4. Hence, the frequency and method of calibration should be based upon current accepted practice. But there is also room for non-compliant particle counters in the note section: Some particle counters cannot be calibrated to all of the required tests in ISO 21501-4. If this is the case, record the decision to use the counter in the test report.6. Tube length for particle counter

Previously, no definitions were made for the sample tube length in cleanroom classifications. Particle counter manufacturers usually send a 3 m sampling tube with each device and many end users connect it directly to a particle counter. But, a 3 m tube with cranks and excessive bends, could cause particle loss in tubing. Particles of more than 1 μm could be trapped inside this tube even if it is a tube with a Teflon inner coating. Annex C now has a new definition for the sample tube length: The transit tube from the sampling probe inlet to the LSAPC sensor should be as short as possible. For sampling of particles larger than and equal to 1 μm, the transit tube length should not exceed the manufacturer’s recommended length and diameter, and will typically be no longer than 1 m in length.Will it also be effective for particle monitoring systems? These systems have a different approach. Sample tubes are mostly inside rigid stainless-steel tubes and each bend has a certain radii. As short as possible is the best approach but in some cases, due to the restriction of installation locations, sample points and production dynamics, particle counters and isoprobe locations could be more than 1 m. In such case, consider the following precautions:

- The sample tube should be inside a stainless-steel shield to protect it from unnecessary movements, which can cause particle count peaks and false counts

- Bends should be limited and within certain radii.

The ASTM F50, the standard practice for continuous sizing and counting of airborne particles in dust-controlled areas and cleanrooms using instruments detecting single sub-micrometre and larger particles, defines tube bends radii as: a maximum transit tube length of 3 m for particles in the size range of 2-10 μm. If a flexible transit tube is to be used, then no radius of curvature below 15 cm shall be used.

Follow these six step to comply with the new standard quickly and safely. There are also detailed revisions such as “Cleanliness classification in cleanrooms” to be changed to “Cleanliness classification in terms of particles in cleanrooms”. However, it is unlikely any of these revisions will affect our day to day working life.

This article will appear in the October issue of Cleanroom Technology.