Quite early during the air and space era in the 1950s and 60s, it was discovered that visible cleanliness was not good enough. It was also discovered that the surrounding air in a room harbour enormous amounts of particles, invisible to the naked eye, and therefore not noticed by the personnel. The first cleanrooms were developed and used to overrun these issues. However, it was at the same time discovered that the personnel working in these clean controlled environments, turned out to be the greatest source of particles, of which, due to natural reasons, were not easily controlled.

The human source

We, as humans, perform a never-ending process of renewing the outer layer of our skin. Snakes and some insects renew their skin by exuviation, which is a process taking place here and now, leaving their discarded outer layer of skin out in the nature. We also renew our skin, but this is a continuous process, taking place ongoing constantly. This means that our discarded skin is not in the form of a shell, instead it is discarded as minute particles that are dispersed away from our body. Many of the generated and released human skin particles are trapped and collected in the garment that we wear, but quite large numbers of skin particles are dispersed out into the surrounding air.

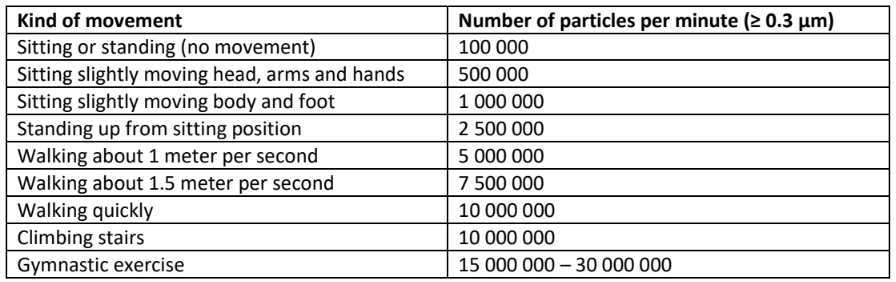

NASA published data on particle generation from humans, and the most legendary result is shown in Table 1. This table shows the number of particles, with a size equal to and larger than 0.3 micrometre, generated at different physical activities. When sitting totally still and silent, a human being is generating in average 100 000 particles per minute. When becoming more physically active the number of particles generated will increase quite dramatically. The result presented by NASA is “average of a large number of measurements”, and furthermore, there is no description on how these measurements were performed on the different test persons (male, female, age, etc). This lack of knowledge makes it quite difficult to reproduce such a test today. It would be interesting to find out the difference between the situation in the middle of last century and today. It is in fact more than 70 years ago.

Table 1. Results presented by NASA showing the number of particles generated by persons performing different activities, measured as the number of particles with a size greater to and equal to 0.3 μm

At the Design Centre, University of Lund in Sweden, we performed tests on humans, not to reproduce what NASA did, but merely to see if these numbers are still valid. We did not get the same nice, rounded numbers as NASA, but we found that the number of particles generated are following the same pattern as NASA when becoming more physically active.

The particles generated by humans are dead discarded skin particles, with a size so small that they are not possible to identify as single particles by a naked human eye in normal day light. The visibility level for a healthy human eye, in normally lightning and without any optical aid, is approximately 40 micrometres. The skin particles released from our skin have a size of less than 30 micrometres.

Human skin debris

Since cleanrooms are defined as and used to minimise the number of particles in the surrounding air, particles generated by humans will have an impact on the overall cleanliness, and thus become a contamination control issue.

In the life-science industry and in hospital applications the focus is on living particle, i.e., particle that can proliferate - the ones that we normally call microorganisms. Are skin particles generated by humans considered as critical contaminants? The answer to this question is YES, both in non-biological industries as well as in life-science. This is because the skin surface of our body is totally covered with microorganisms, most of them belonging to what we call the human normal flora. In practise this means that all skin particles generated and released from our bodies are carrying microorganisms, like flying carpets carrying microorganisms as passengers. This indicates that all particles generated by humans are considered as critical “viable” particles within the life-science industry and health care.

Cleanroom operator behaviour

Bearing in mind what is discussed above, a cleanroom operator is a critical tool when producing and handling critical products, regardless of if we are working within the microelectronics industry or within pharmaceuticals. The best solution is to eliminate all aspects of human presence, but this has so far been difficult, not saying impossible. Instead, the behaviour of operators in cleanrooms must be controlled in such a way as to minimize the possibility for contaminating the product and the process.

Controlling particle generation and dispersion is done by, for example:

- Keeping a calm pace

- Not leaning over products or processes

- Not talking when close to the product or process

It is of outmost importance that cleanroom operators are educated and trained in contamination control, i.e., that they know they are the largest, and in many cases also the most critical source of contaminants, and that they know how to behave correctly.

Cleanroom garments

In a book published in 1992 one of the pioneers from NASA wrote “Cleanroom clothing and gloves are the primary barrier keeping contaminants, generated by personnel, from being emitted into the cleanroom and deposited on products”. It is vital to understand that the garment used by cleanroom operators are not only the primary, but in many cases also the only barrier - this is why cleanroom garments are extremely important and, most of all, must have the correct function, i.e. they should be clean enough and, when used in higher grade cleanrooms, have a good enough coverage in order to act as a barrier or a filter minimising particles generated by the operators being dispersed into the cleanroom environment.

Cleanroom garments consist of two different types of materials:

- Woven, textile materials, that can be repeatedly laundered and even sterilised

- Non-woven polymeric material, that are intended for single-use

Non-woven fabric

Textile fabric

The difference between these materials, from a contamination control point of view, is their filtration ability. Textile materials act like a sieve or a strainer, whereas non-woven material acts more like real filters. The textile cleanroom garments, that are intended for repeated use, must be laundered and in some cases sterilised prior to use.

Looking more closely at cleanroom garments, not much has in fact happened over the last 20 years. This is quite unique as compared to the development of isolators, RABS (Restricted Access Barrier Systems) and closed single-use process system. Have we forgotten the operators, or is the general feeling that operators in cleanrooms are no longer an issue? Cleanroom garments are still the primary and only barrier between the operator and the cleanroom environment.

The laundering and sterilisation cycles of textile cleanroom garments will have a negative impact on the garment, decreasing its ability to act as a filter over time. Consequently, the draft of Annex 1 (2020) states that “Damage to garments may not be identified by visual inspection alone, so the qualification should consider any necessary garment testing requirements”. In other words – There is a need and desire to develop some sort of integrity testing on critical reusable cleanroom garments.

Operator training and knowledge

Cleanroom technology suffer two major issues. First, the contaminants that is to be controlled are invisible, and furthermore, the movement of air, which is a major vector in the transportation of contaminants, is also invisible. To handle an invisible “enemy” is extremely difficult, and therefore all personnel in a cleanroom (process operators, cleaning operators, personnel working with maintenance and repair, quality control etc) must have a thorough “know how” on how to behave and work. “Know how” is of course extremely important but it is not enough. The foundation of “know how” is “know why”, and unfortunately “know why” has been overlooked for the last 20 years or so.

The latest draft of Annex 1 takes account for this lack of knowledge and states “All personnel including those performing cleaning, maintenance, monitoring and those that access cleanrooms should receive regular training, gowning qualification and assessment in disciplines relevant to the correct manufacture of sterile products”.

"This training should include the basic elements of microbiology, hygiene, with a specific focus on cleanroom practices, contamination control, aseptic techniques and the protection of sterile products … and the potential safety implications to the patient if product is not sterile”.

"The level of training should be based on the criticality of the function and area in which the personnel are working”.

What does this mean?

There was a post on Twitter in late 2020 written by a former member of PDA (Parenteral Drug Association, US) acknowledging that cleanroom operators are extremely critical in pharmaceutical cleanrooms. The post continued: that the best solution is to remove all operators from critical cleanroom applications and that this would be possible already today by using all the newly developed techniques, like isolators, robotics, automation etc.

Personally, I find this comment quite strange. For example, not all applications in cleanrooms are suited to be handled in isolators. Robotics are, in the same way, not always appropriate to use. From my point of view, I think that quite a lot of cleanroom applications can be performed without operators present, but approximately 50% of all pharmaceutical applications needs operators, and this includes all cleanroom Grades ranging from D to A.

The most important aspect when using cleanroom operators is to give them the best possible opportunity to perform well, meaning not contaminating the products or processes that are handled.

Cleanroom operators are our most important tools when enclosures and robotics cannot be used. Take good care of your cleanroom operators – Your cleanroom operators are your most important asset.