The choice of mopping system can be crucial to the successful cleaning and disinfection regime for a cleanroom environment. With the advent of new substrates and advances in hardware there is more choice than ever when it comes to cleanroom mopping systems and the mop heads offered for use with them.

A variety of methods are available for cleaning and disinfecting large areas of a cleanroom, including fogging systems, pressurised sprays, gassing modules or manual disinfection with mops and buckets.

However, even when using a more automated system, physical removal of soil and residues should ideally be carried out on a routine basis, as over time a build-up can affect the efficacy of any disinfectants used. So what considerations need to be given to the choice of manual system used?

The mopping systems currently available can be divided into six main categories (see table 1):

Table 1: mopping systems currently available

| 1. | Single use, dry, disposable mop heads: Used with a traditional bucket system of detergent or disinfectant. Allow for re-application of fluid. Used on a sessional basis and disposed of. |

| 2. | Single use, presaturated mop wipes: presaturated with disinfectant or detergent. Cannot be recharged. Used once and disposed of. |

| 3. | Reusable, dry mop heads: Used with a traditional bucket system of detergent or disinfectant. Allow for reapplication of fluid. After each use mop heads are sent for laundering and where relevant sterilisation and reused for a validated number of times. |

| 4. | Reusable, presaturated mop heads: Presaturated with disinfectant or detergent. Cannot be recharged during a session. After each use mop heads are sent for laundering and where relevant sterilisation and reused for a validated number of times. |

| 5. | Single use, dry mop heads presaturated at point of use: Used with a mop preparation trolley, dry mops are saturated at the start of a session. Mops cannot be resaturated during the session. Used once and disposed of. |

| 6. | Reusable, dry mop heads presaturated at point of use: Used with a mop preparation trolley, dry mops are saturated at the start of session. Mops cannot be recharged during the session. After each use, mop heads are sent for laundering (and where relevant sterilisation) and reused for a validated number of times. |

Within these broad categories sits a further sub-division of mop head types.

Cleanroom mop heads are available in a range of shapes and sizes: flat mops, string or Kentucky mops, self-wringing mops, t-bar mops, mop wipe frames and speciality tools for isolators, curtain cleaning, vessels etc.

Considerations for mopping system

As the cleanroom classification gets higher, the amount of space available for cleaning equipment tends to reduce, so the ideal system for one area of the facility may not be the same as it is for another.

Previous work carried out has shown that the use of multiple bucket systems significantly improves the effectiveness of the cleaning process.

Work carried out by Dr Smith of Aston1 showed that the use of a multiple bucket cleaning system can have a significant effect on the environmental results achieved.

He concluded from work carried out over three months, in three different grades of room (using a single bucket system, a triple bucket system with standard hospital disinfectant and a triple bucket with sterile specialist cleanroom disinfectants), that the use of a triple bucket system and specialist cleanroom disinfectants significantly improved the environmental results compared with traditional cleaning methods.

The use of a double bucket system allows one bucket to be designated as the waste bucket that the mop is wrung into.

The mop is never placed into this bucket. The second bucket holds the disinfect or detergent solution, the mop is recharged from this bucket once it has been wrung into the waste bucket.

A triple bucket system with a clean water rinse bucket further improves this system, as the ‘dirty’ mop can be rinsed and wrung out prior to being recharged in the disinfectant or detergent solution, completely protecting the application solution from contamination.

Various designs of multiple bucket system are available, but consideration needs to be given to the size of the cleanroom and the space available for the storage of the bucket system.

Some double bucket systems are specifically designed for smaller units, and removable trolley handles ensure systems will fit under a bench. However, for very small facilities options 2 or 4 shown in table 1 may be the best solution.

Single use presaturated mop wipes are ideal for smaller facilities as the need for any bucket system or access to water of the required quality is eliminated.

However, care must be taken to ensure the mop wipe system has proven compatibility between the wipe and the disinfectant.

Many disinfectants can be adversely affected by the wipe substrate2. Efficacy testing should be carried out to show the presaturated wipe remains effective over its shelf life.

Mop wipe frames need to ensure there is sufficient ‘give’ in them to get into all crevices and scratches in the cleanroom surfaces as the mop wipes themselves have no padding.

This lack of padding also decreases the absorbent capacity of the mop, reducing the amount of coverage a typical mop wipe can provide. A typical presaturated mop wipe will cover approximately 3m2.

Mop wipes are very convenient and ensure contamination is being physically removed from the cleanroom.

Make sure the mop wipe frame is easy to use, both for fixing and removing individual wipes, without snagging gloves and that it has no sharp edges protruding beyond the wipe.

Another option that eliminates the need for a traditional bucket system is to have presaturated reusable mops delivered as part of a laundry contract.

The mops, already presaturated with your choice of disinfectant, are delivered to your facility in sealed bags ready for use.

Once used, the mops are packed back into sealed bags and sent back to the vendor for laundering and sterilisation before being returned to the facility.

These mops cannot be recharged during a session so sorbent capacity is crucial to make them cost effective as they can be used only once in each session.

Small facilities may be able to simply add mop heads to the mop frame straight from the bag, eliminating the need for any additional hardware. Larger facilities using this type of system may still need some hardware to carry the mops into and out of the cleanroom.

If a presaturated mop system is being used with certain disinfectants, such as amines or quaternary ammonium compounds, care needs to be taken to ensure the correct amount of active is released to the surface.

Previous studies have shown that the binding effect of positively charged chemicals to negatively charged mop heads can reduce the amount of active released to the surface by up to 70%.

Due to their ability to hold large volumes of fluid, many reusable mops are manufactured from microfibre materials. Microfibre mops are negatively charged.

A study by R. Bloss et al 3 looked at the absorption of the active ingredient of different surface disinfectants onto various types of fabric.

The results showed that the quat was strongly absorbed onto both the cellulose based wipes (up to 61% after only 30 mins) and the viscose rayon wipes (up to 70% after 30 mins).

The paper concluded that an effective surface disinfection regime has to include the selection of an appropriate fabric.

Other research has come to the same conclusion; MacDougall and Morris4 showed that a nonwoven wipe released an average of 90% of the original concentration of quaternary ammonium solution after 8 hours but a cellulose based wipe released only 21% of the original concentration.

The studies went on to discuss various ways in which this problem could be overcome: by careful selection of the substrate; by allowing for the loss and starting with a higher concentration of quat in solution to allow for the binding so the amount released is still above the required kill level; or – not necessarily practical – by using a very large volume of solution to a small amount of mop material.

Even over short time periods, a drop in active ingredient was observed that could significantly affect the overall effectiveness of a biodecontamination regime.

Even mop heads presaturated for use in that session need to be assessed to ensure there is no drop-off in active ingredient being used.

It must also be remembered that some mops are not compatible with bleach-based disinfectants; for example, a split micro-fibre mop containing nylon will not be compatible with bleach-based disinfectants.

Reusable vs single-use

Best practice for both mops and wipes in a cleanroom environment is to use single-use disposable products. This reduces the risk of cross contamination and ensures that contamination is physically removed from the cleanroom environment at the end of a session.

However, laundering and re-using can be a cost-effective alternative to single use disposable products, if all validation requirements are met.

Laundering typically involves a contract with an industrial laundry, and if a sterile product is required either an autoclave process or an irradiation provider needs to be included.

An immediate issue can result: if the mops are not barcoded with your own details, do you know whether you are getting your own mops returned?

Barcoding will enable tracking and control through the laundering/sterilisation process to ensure a customer receives the same mops through repeated processing.

Microfibre has a high sorptive capacity of around 6 to 8 times its own weight in water. This high sorptive capacity and fast wicking ability make it very suitable for mop applications.

However, microfibre is not an inexpensive fabric and in many instances this high initial cost is balanced by relaundering.

Microfibre is very delicate and can be easily damaged by high heat or harsh chemicals; this can lead to a mop degrading over time and affecting both the cleaning ability and the sorbent capacity of the mop over time.

It is the unique split structure of microfibre that gives the mop the ability to pick up particles even when dry, and it can easily remove residues often without solvent. The split fibres create microscopic ‘hooks’ that collect and hold dust, dirt and particles.

The virgin fabric is very soft so won’t scratch and damage surfaces; however, care should be taken when re-using mops as the very structure that makes them so good at picking up particles also means that particles get stuck in the fibres, which can then scratch a surface.

As cleaning is carried out from the cleanest to the dirtiest area within a cleanroom complex the soil load on mops can be significantly different. It is not easy for the laundry to guarantee getting all the mops back to the same level of cleanliness every time.

As with a disposable mop, the reusable version requires the same initial testing and validation to ensure it meets the application and environmental requirements.

Since disposable mops are made from new materials to a validated process they provide a consistent and predictable performance and result.

This result remains constant even over a long period of time as a new mop with the same parameters is used every time.

With a reusable product there must be serious consideration given as to whether the product continues to perform as specified over the period of relaundering.

This becomes even more critical for sterile products where the irradiation parameters are also set and validated for virgin materials.

Repeated use of gamma irradiation, for instance, can render materials brittle and accelerate ageing.

The use of virgin materials that are less likely to have been exposed to unknown or potentially variable conditions and contaminants simplifies the validation process.

Understanding the real risk of using reusable products can be accomplished only through repeated periodic revalidation.

Choice of mop and substrate

Key factors for consideration when choosing which type of mop to use include ease of use, coverage, cleanliness (particles and fibres), compatibility with chosen disinfectants and detergents, availability of sterile product if required, packaging (do individual mops need to be double bagged?) and cost.

Also, the type and roughness of flooring needs to be taken into account and the amount as does the type of soil/residues that need to be removed. If the mop is to be used for cleaning and not disinfectant application, a mop with a textured surface or panels of a more abrasive material may be required.

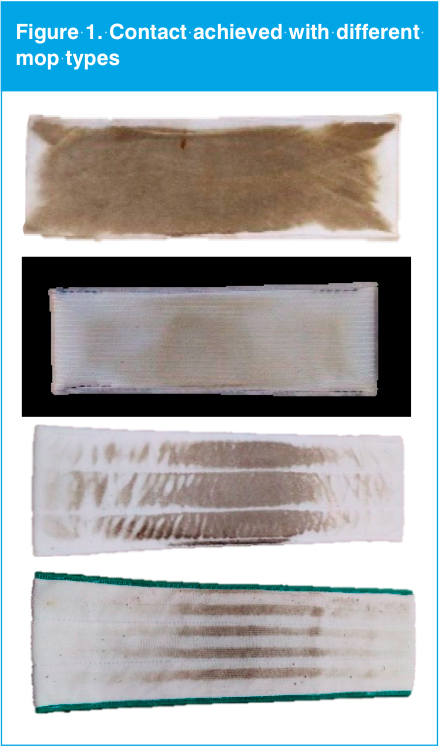

Surface contact can vary dependent on mop head frame, mop and flooring type

Dependant on the option chosen, the criteria for selecting the ideal mop head may change. If a reusable mop is required, materials of construction need to stand up to rigorous relaundering and sterilisation.

For example, not all mop construction is suitable for autoclaving, so check manufacturers’ data carefully.

Presaturated mops or mops presaturated at point of use cannot be recharged, so coverage will be key to the number of mops needed on a sessional basis.

Mops with higher coverage will be more cost effective. When dry mops are used with a bucket system, greater coverage will mean fewer trips back to the bucket to recharge.

Mop head frames are available in a variety of sizes. The larger the mop head the more coverage is achieved in one pass; however, if it is too large the mop becomes unwieldy and difficult to handle.

Small mop heads maybe better for inside and around fitted equipment. Low profile mops help to get under fitted equipment.

The combined weight of the wet mop, handle and frame is crucial to correct technique being maintained.

A mop that is too heavy for an operator to use will almost certainly result in poor technique and missed areas

A swivelling joint on the mop head also helps to maintain good contact with the wall and promotes good technique. This joint needs to be neither too loose nor too stiff for optimum results.

The mop and mop frame combination needs to ensure good contact with the surface to be cleaned or disinfected.

As manufacturers reduce the amount of material in the mop head frame to save on weight, it needs to be checked that this has not compromised good contact and the created pressure points (see Figure 1).

Friction between the floor and the mop can also create drag on the mop and reduce effective coverage.

High levels of friction can also render the mop system almost unusable. The only way to be certain is to trial any mop system thoroughly on all floor surfaces before purchase.

It is highly likely that the same mop and mop head frame is not suitable for all areas of the cleanroom or rooms of differing grades.

The mops that have the greatest capacity and therefore coverage are string mops; however, it is not easy to use this type of mop with a best practice ‘pull and lift’ technique, nor is it suitable for use on walls or ceilings. For outer areas, these mops can be very useful.

Flat and pocket mop frames are very suitable for cleanroom use, giving good coverage and allowing good technique to be achieved.

Specially designed mops are available for cleaning isolators and RABS, vessels, curtains and coving, although the factors that affect the choice of mop substrate are all still relevant.

Each mop must be validated for use in its particular environment and care taken that it doesn’t add to the contamination load.

Mop heads are available in many substrates: polyester/cellulose mop heads are cost effective with good coverage but higher particle generation. Quat binding will also occur with cellulose-based mops.

Man-made fibres such as polyester will reduce the particulates generated and provide good chemical compatibility. Cost will inevitable be higher.

Thin mop covers are available that can be used in conjunction with many mop heads to extend the sessional use and reduce costs.

Reusable materials include 100% polyester and microfibres. Microfibres split fabric makes this substrate less clean than standard polyester knits.

Polyester-covered foam creates a highly sorbent mop, with a foam core and a high-quality fabric being presented to the surface.

Mop testing

There is no standard test method for comparing mop capacity or coverage. Manufacturers’ datasheets will normally include information on the dry weight of the mop, the overall capacity, particles and fibres generated and non-volatile residues.

Due to variations in test parameters in the same way as when comparing wipes, valid product comparisons may be obtained only through side-by-side testing in the same test facility, under similar conditions.

This becomes even more relevant when trying to ascertain the coverage that can be achieved with each type of mop.

Many factors come into play, including how much the mop is wrung out before mopping is commenced, the floor type on which the test is carried out, the fluid used, the pressure applied, room conditions of temperature, humidity and air change rate and the subjective point at which the tester decides that coverage is no longer sufficient.

So while manufacturers’ testing can provide a starting point and show comparable data for mops tested side-by-side in the same test facility under similar conditions, product trials in your own cleanroom will be crucial to successful introduction of a new mopping system.

References

1. J. Smith. Eur. J. Hosp Pharm. 2005; 11:1-4.

2. K. Rossington. Cleanroom Technology, 2013. 6 18-23

3. R. Bloss, S. Meyer, G. Kampf. J. of Hospital Infection, 2010; 75 (11) 56-61

4. K.D. MacDougall and C. Morris, Infection Control Today, 2006; 6 62-7

The Author

*Karen Rossington is a marketing consultant for Contec Inc