The pharmaceutical, medical, hospital and food industries all share a similarity in that they require cleanrooms to properly operate to maintain their hygiene level. A cleanroom is an enclosed space or area where the environment is controlled to prevent contaminants. Dust, airborne particles, chemicals vapours, water vapours, and microbes are all examples of pollutants /contaminants that a cleanroom environment prevents.

One of the main things that makes a cleanroom "clean", is the air distribution & filtration system. By using HEPA and ULPA filters, cleanrooms can prevent contaminants from entering the "clean" space and compromising the integrity of the cleanroom. But it's not just about the filtration used, it's equally important to establish the proper airflow pattern in the cleanroom for optimal filtration.

Air distribution strategies for cleanroom

The cleanest air environment can be achieved with a unidirectional (laminar) airflow pattern. Low-level return airflow plays a key role in creating a unidirectional flow pattern in the cleanroom. Unidirectional (laminar) airflow means the air in a designated space is all blowing in a uniformed pattern, in terms of velocity and direction.

It makes the air inside an enclosed space such as the cleanroom move safely and free from contaminants. Particles that enter a room with laminar airflow will only stay in the room for a short time and be filtered out quickly through HEPA filters.

When primary existing air mixes with the induced room without any proper directional flow, it is classified as turbulent airflow. This airflow is best used when concentrating clean air in select points of the cleanroom.

Turbulent airflow keeps the air in a cleanroom in constant motion.

Achieving unidirectional airflow

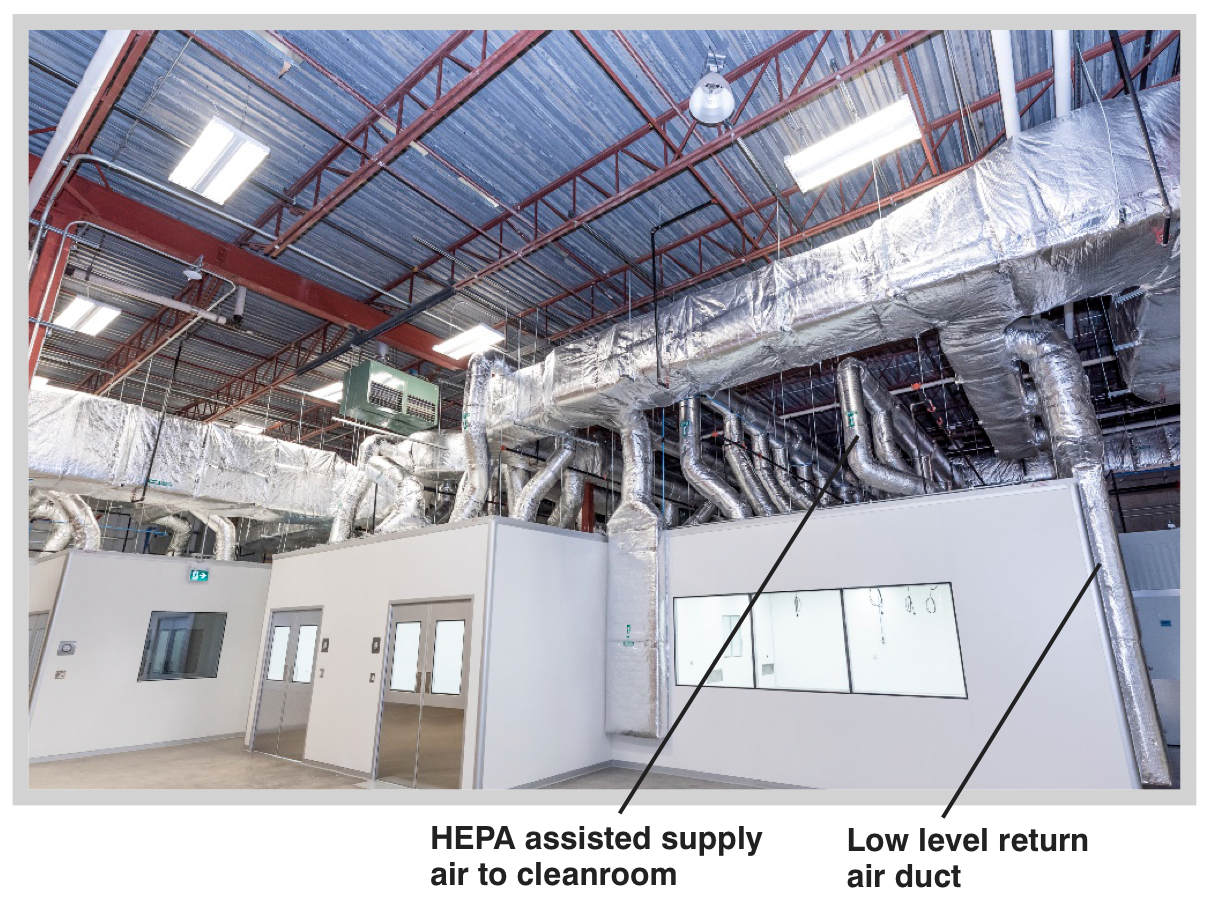

Since the unidirectional airflow pattern is used to achieve the cleanest air classes, it's understandable that a low-level air return is important to have in any cleanroom. In order to achieve a unidirectional airflow pattern, you would need to have an air supply on the ceiling and a low-level air return towards the bottom of the room.

Airflow would come down from the ceiling and would be pushed down to the floor and into the low-level air return, resulting in a unidirectional airflow pattern.

Equal temperatures

The suggested temperature of a cleanroom should be 21°C in most of the application unless specific to the product. Sometimes a fluctuation of 2°C is acceptable. Maintaining and controlling cleanroom temperature is important for your own comfort and the integrity of the cleanroom.

Low-level air return will help maintain an equal temperature in the room. Naturally, cold air is heavier and it typically settles towards the bottom of the room. While hot air is lighter and gradually rises to the top of the room. A low-level air return grill will maintain balance between the hot and cold air, resulting in an equal temperature, no matter where you are in the cleanroom.

You need an air supply on the ceiling and a low-level air return

Balanced return air is an advantage of having a low-level air return duct. Air balancing is another important factor for added comfort when working inside the cleanroom.

A good return airflow keeps the room at a maintained temperature. It makes people breathe easy and the room feels warmer. It also keeps away contaminants that can potentially compromise the integrity of the cleanroom.

It's in the air

Air return ducts installed on a low-level or somewhere on the wall promotes better air quality. The air is cleaner, fresher, and cooler if the air return in your cleanroom is installed and working properly. Air returns installed up in the ceiling tend to produce low-quality air due to poor air distribution. Poor air circulation attracts contaminants which defeats the purpose of a cleanroom. Air quality is important in an enclosed space such as the cleanroom. Not only does it prevent contaminants, but it also provides a more comfortable setting for cleanroom workers.

Low-level air return is more efficient than high-level air return if we're talking about air distribution. Hot and cold air mixes when the air return duct is up the ceiling making the room feel hotter.

The air pushes in and out of the air supply efficiently when the air return duct is at a low level. It helps achieve equal air distribution inside the cleanroom which allows good ventilation. Poor air distribution can contaminate the cleanroom which fails to meet the cleanliness specification.

Without the help of low-level air return filtration, you may find that the HVAC unit may become compromised. MERV-rated filtration integrated into the low-level air return prevents biological or product-related impurities from going to the HVAC unit. This aids in improving HVAC usage and efficiency.

Cold air is heavier and typically settles to the bottom of the room

Low-level air returns come equipped with filters that prevent any contamination from going out of the room. You might be wondering, what's the point of filtering air that is leaving the cleanroom? There are a couple of reasons that make this important to consider.

Hazardous products

Some cleanrooms are used to manufacture hazardous products, particularly in the pharmaceutical industry. Without the proper protection, these products can be harmful to people working in and around the cleanroom.

When working with pharmaceuticals, it is common for powder to be spread around the room, naturally settling on the floor. With a laminar airflow and low-level air return, these hazardous chemicals are trapped in the air return filtration.

Easy maintenance

Another factor that is significantly impacted by low-level returns is the maintenance. Since low-level air returns are found at the bottom of the room, it is extremely convenient to replace the filters as part of your regular maintenance of the cleanroom. In fact, modular cleanroom panels can be manufactured with prefab low-level return in the wall and space for grill integrated to make convenient for operation.