ProCleanroom has engineered, manufactured, installed and ISO validated a fully customised Panelbloc cleanroom for a global precision parts supplier with headquarters in the Netherlands. The compact 28 sqm, ISO Class 6 cleanroom is specially engineered and installed to our customer-specific requirements and is built to house a highly UV sensitive process.

The flush walls and ceiling accommodate fast and maximum cleaning of the areas and allow for maximum cleanliness performance. With its H14 HEPA filtration and innovative design, the cleanroom easily achieved an ISO class 6 classification.

The cleanroom is equipped with UV filtered LED lighting blocking the sub 500nm light spectrum hence the yellow effect making the area compatible for a lithography process. The cleanroom area is accessible through a self-closing swing door from the already existing cleanroom, this new area is not accessible from outside for access restrictions. This reduces the contamination transfer between the different areas to an absolute minimum.

To ensure optimal working conditions, the cleanroom is subject to strict specifications.

Temperature and relative humidity are continuously measured inside the cleanroom and regulated where required. A high-end air handling system has been utilised for optimal climate control. This ensures an extremely time stable high-resolution temperature control of 21 degrees Celsius with a maximum deviation of +/- 1 Kelvin and humidity level of 50% +/-10. The self-regulating cleanroom operates within very small margins for upmost quality performance.

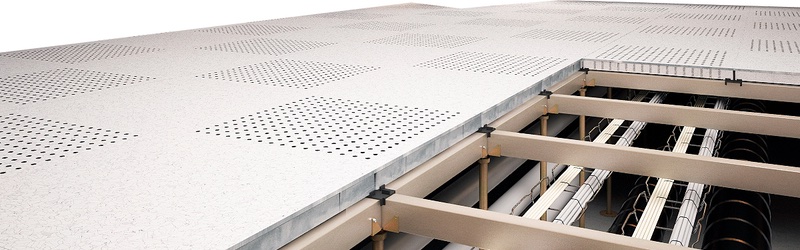

The cleanroom is equipped with raised flooring

The cleanroom is equipped with raised flooring. The raised flooring offers out-of-sight housing of utilities for maximum work space utilisation and lowest contamination risk. The local perforation of the flooring ensures optimal air distribution through the cleanroom area. Easy modification is possible if required in the future.

Direct benefits for the user:

- Maximum cleanliness performance due to fully flush walls, floor and ceiling.

- Raised perforated flooring for maximum airflow performance and cleanest furnishing of the cleanroom

- Bespoke climate control to ensure a very stable high-resolution temperature and humidity control for highly sensitive process.

- Full turnkey solution: ProCleanroom is responsible for design, installation and validation.

- Maximum cosmetic appearance.

- Lowest power consumption and operating costs in the market.