Removing bacterial contamination from foodstuffs is a challenge. Traditional pasteurisation and sterilisation methods rely on the application of heat (using heat exchangers or autoclaves) in both batch and continuous operation.

This thermal treatment, however, threatens a variety of different valuable food constituents such as vitamins, proteins and enzymes. Thus, current developments in state-of-the-art food processing aim towards non-thermal technologies.

Emerging, non-thermal technologies in food processing address specific consumer needs towards safe, healthy and minimally processed foods. Taking advantage of their specific potentials and opportunities, including the understanding and control of the complex process-structure-function relationships, they offer the possibility for a science-based development of tailor-made foods.

The collection

of kinetic data, especially on microbial and enzyme inactivation,

has laid the groundwork for targeted processing

Among these technologies, high hydrostatic pressure (HPP) and pulsed electric fields (PEF) have already been implemented successfully into industrial applications; both methods demonstrate the potential of establishing new routes for process and product development by interfacing science and manufacturing.

Significant science-based achievements have been made to better understand the basic principles underlying HHP and PEF methods. In addition, the collection of kinetic data, especially on microbial and enzyme inactivation, has laid the groundwork for targeted processing. Whereas HPP and PEF allow a volumetric treatment of foods, other technologies such as cold plasma (CP) are designed for surface decontamination.

Plasma applications exist in medical device technology and therapeutic medicine and include decontamination.

For the food industry, research is focussing on the interaction between plasma and biological cells and tissue as well as on the plasma diagnostics. Efforts are made to understand and control the complex behaviour of cold plasma to lay the groundwork for future industrial application.

Application concepts

For the HPP treatment, the packaged food is deposed in a carrier and automatically loaded into an HPP vessel. The pressure transmitting media, usually water, is pumped into the vessel.After reaching the desired maximum pressure (of around 6,000 bar) the pumping is stopped and the pressure is kept constant during a dwell time of about three minutes. In contrast to a thermal process where temperature gradients occur, all molecules and bacteria in the HPP vessel are subjected to the same amount of pressure at exactly the same time due to the isostatic principle of pressure transmission.

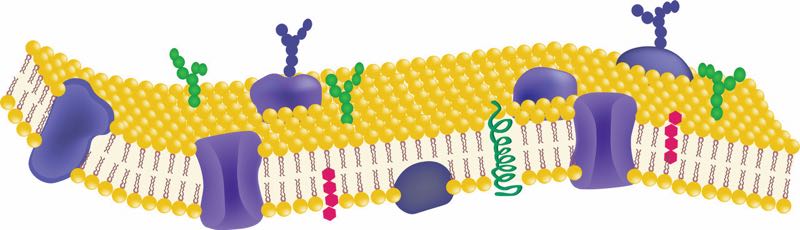

The lethal effects of HPP on vegetative microorganisms are attributed to enzyme inactivation and cell membrane rupture.

The primary structure of low molecular weight molecules, like vitamins or flavour compounds, is rarely affected by HPP so that products retain their original fresh taste and nutritional content.

Industrial scale HPP methods are typically batch processes and pressure vessels used for commercial food production have a size of around 400L.

In contrast, PEF treatment can be applied as a continuous flow-through process for liquid foods. When exposed to high electric field pulses the cell membranes of spoilage and pathogenic bacteria develop pores that result in the loss of cell content and cell death.

The electric pulses are high in voltage (e.g. around 20 kV/cm), but short in time; usually in the range of microseconds.

Cell membrane as target structure for PEF or HPP

The mechanism of pore formation is called electroporation and is mainly based on a mechanical electro-compressive force affecting the cell membrane. Hence, pulsed electric field technology does not rely on heat for the inactivation; products can be treated at lower temperatures compared with conventional thermal pasteurisation.

Effective inactivation for most of the spoilage and pathogenic microorganisms has been shown in the range of 4-6 log cycles, and colony count reductions (depending on treatment intensity, product properties and type of microorganism) are comparable to traditional thermal pasteurisation. Bacterial spores and viruses are not affected by the PEF treatment.

Besides the inactivation of bacteria in the whole volume of a food, the decontamination of the surface of a food or a packaging material might be sufficient to obtain a safe and shelf-stable product. For this purpose, cold plasma can be applied.

Plasma is an ionised gas that contains different reactive species and radicals as well as UV light, which are responsible for the antimicrobial effect. Because emitted species react with bacteria, they may also affect food components such as water, lipids, proteins and carbohydrates. Further research is needed to investigate occurring effects.

The most suitable system for food processing is an atmospheric-pressure plasma device where no extreme conditions are required and low temperatures can be realised.

Atmospheric-pressure plasma is commonly generated by corona discharge, dielectric barrier discharge or plasma jet. Plasma technologies in food processing with direct application to food are not yet established, but concerted research efforts are made to understand and to apply atmospheric pressure plasmas as a sterilisation method.

Liquid food preservation by PEF

HPP and PEF are the most prominent emerging, non-thermal technologies. While the first is a truly non-thermal process able to pasteurise foods even at ambient temperatures, it also ranks among the most expensive food preservation technologies by far.

PEF treatment, on the other hand, is accompanied by a certain temperature increase, but with the benefit of a continuous mode of operation and consequently distinctly lower processing costs.

Microbial inactivation of vegetative cells via PEF offers pasteurisation with low energy input, selective inactivation of microorganisms depending on cell size or shape, as well as retention of bioactive heat-sensitive food compounds while inactivating pathogenic microorganisms and increasing product shelf life and safety. Considering food preservation, PEF has mainly been used with fruit juices and other fluid foodstuffs. Here, relatively low treatment intensities are already sufficient for successful pasteurisation since the low pH positively contributes to the effectiveness of the treatment.

Recent investigations revealed conditions under which Listeria in more viscous whey protein solutions can be safely eliminated by PEF, while simultaneously preserving valuable nutrients. Temperatures of 20°C and an acidic environment with a pH value of about four were identified as ideal conditions for electroporating bacteria in protein solutions like the whey protein.

Recent investigations revealed conditions under which Listeria in more viscous whey protein solutions

can be safely eliminated by PEF

The results obtained by the team from the University of Natural Resources and Life Sciences (BOKU), in close collaboration with an international food company and the EQ-BOKU VIBT GmbH as equipment supplier, have now been published in the Journal of Food Engineering (Schottroff et al., 2018).

The study compared two concentrations of whey proteins (2% and 10%). A Listeria strain that is harmless to humans was then added to these solutions and the degree of inactivation resulting from PEF of different intensities was compared.

A temperature of between 20°C and 40°C, and a pH value of four or seven was selected. After electroporation, the residual level of sensitive nutrients, such as vitamins and immunoglobulins, and the Listeria concentration were measured.

The study makes an important contribution to the development of more efficient and less damaging methods of removing germs from sensitive products

Temperature was found to play a decisive part in this process. The energy produced by the pulsed electric field causes the medium to warm quickly, which damages many valuable proteins. This effect increases in line with the strength and duration of the electric field, which in turn kills off the bacteria more efficiently.

A low starting temperature of about 20°C and a pH value of four was found to represent the ideal equilibrium, allowing for greater intensity of the electric pulses and, in turn, effective inactivation of the Listeria, without excessively heating up the product.

The study makes an important contribution to the development of more efficient and less damaging methods of removing germs from sensitive products, as well as enhancing overall food safety.

Further possible applications include the preservation of all kinds of different protein solutions, e.g. for pharmaceutical purposes, dietary supplements, infant formulae, or foods for special medical purposes. Apart from pasteurisation, this technology might also be incorporated into novel sterilisation regimes, as it was shown that a combination of heat and electric fields is capable of inactivating bacterial spores more efficiently than heat alone.

Beyond, all types of viscous foods prone to burning upon contact with hot surfaces are well suited for the application of electrotechnologies for preservation purposes, as lower temperatures emerge during PEF processing, and the heat is directly generated within the product, rather than transferred by conduction or convection.

ReferencesSchottroff, Felix & Gratz, Maximilian & Krottenthaler, Anna & B. Johnson, Nicholas & F. Bédard, Matthieu & Jaeger, Henry. (2018). Pulsed electric field preservation of liquid whey protein formulations – Influence of process parameters, pH, and protein content on the inactivation of Listeria innocua and the retention of bioactive ingredients. Journal of Food Engineering. 243. DOI:10.1016/j.jfoodeng.2018.09.003.

N.B. This article is featured in the December 2018 issue of Cleanroom Technology. The digital edition is available online.