When a Fortune 500 company needed to expand its production capacity for automotive glass lamination, they turned to Airkey for a robust, custom cleanroom solution. As a specialist modular cleanroom manufacturer in China, we were tasked with designing and building a 685-square-meter ISO 7 cleanroom (Class 10,000) within a challenging existing metal building. The project required overcoming significant engineering hurdles to achieve the precise temperature and humidity control critical for the sensitive auto glass bonding process. This successful installation highlights Airkey's capability to handle complex, turnkey cleanroom projects for the world's most demanding manufacturers in the automotive supply chain.

Project Overview: Precision for Automotive Glass Manufacturing

-

Application: Automotive glass lamination / windshield lamination

-

Cleanroom size: 685 sqm

-

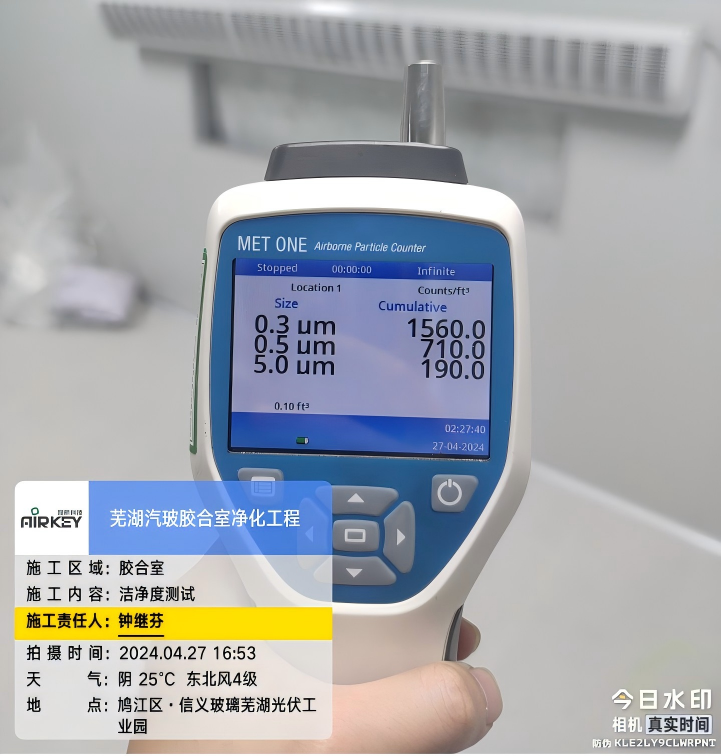

Cleanroom class: ISO 7 (Class 10,000)

-

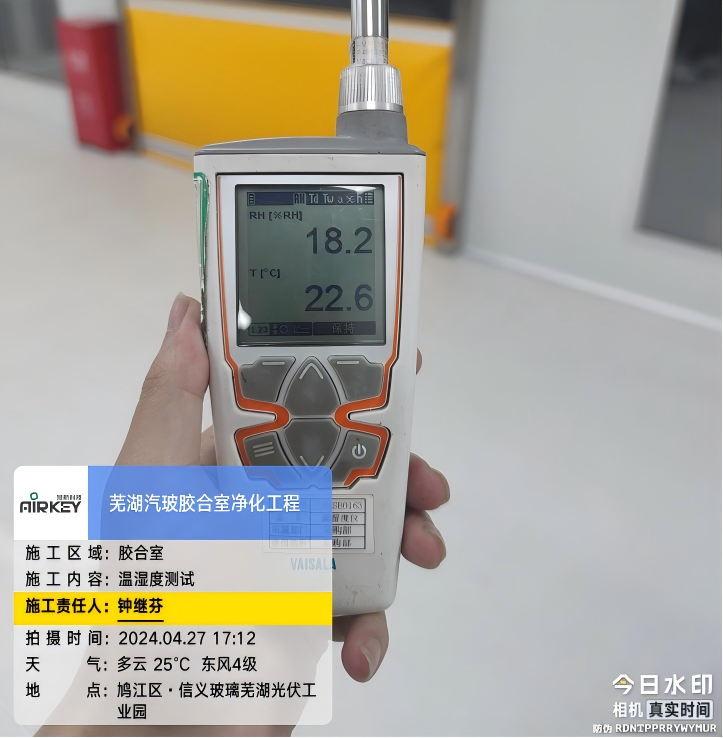

Environmental control: 18–25°C / super low humidity 18–30% RH

-

Key features: Custom HVAC system, rotary wheel dehumidifier, freestanding structure with roof support for AHU

Engineering solutions to overcome critical challenges

-

Combating extreme ambient heat and humidity

Challenge: The host metal steel building created an intensely hot and humid summer environment, placing a massive load on the HVAC system.

Solution: Our engineers performed detailed load calculations and specified a powerful, custom-designed HVAC system for the cleanroom with a dedicated rotary wheel dehumidifier. This industrial-grade system was essential to achieve and maintain the required super low humidity consistently, regardless of external conditions.

-

Managing positive pressure with multiple conveyor openings

Challenge: Numerous conveyor belts passing through the walls created significant openings, compromising the cleanroom's positive pressure. This would normally require a large volume of fresh airflow to compensate, which in turn introduces more moisture, making low humidity control extremely difficult.

Solution: We engineered a balanced cleanroom pressure control strategy. The dehumidification system was specifically sized to handle the increased latent load from the higher fresh air exchange rate, ensuring stable humidity and temperature control was never compromised. -

Creating a freestanding structure in a high-bay building

Challenge: The building's high ceiling made suspension impractical, and the client prohibited any roof penetrations.

Solution: Airkey designed a completely freestanding cleanroom. The structure was reinforced with an internal truss to ensure maximum stability and integrity without relying on the host building, a hallmark of a true modular cleanroom.

-

Supporting heavy external equipment with limited space

Challenge: With no floor space available, the large Air Handling Unit (AHU) and air ducting systems needed to be mounted above the cleanroom.

Solution: We constructed a robust steel structure above the cleanroom ceiling. This framework was engineered to support the significant weight of the AHU and all ancillary ductwork, demonstrating the structural versatility of our prefabricated cleanroom approach.

Proven results for automotive manufacturing excellence

The project was completed successfully, providing the client with a high-performance cleanroom that meets the stringent requirements for automotive glass encapsulation. The environment ensures the highest quality in the lamination process, free from moisture-related defects, enabling our client to meet their production expansion goals reliably.

Why global leaders choose Airkey for industrial cleanrooms

This project exemplifies the Airkey advantage:

-

Problem-solving engineering: We specialize in overcoming complex cleanroom design challenges.

-

Precision environmental control: Experts in super low humidity cleanrooms and stable temperature control.

-

Structural versatility: Capable of designing freestanding cleanrooms and supporting heavy external loads.

-

Turnkey project management: We deliver end-to-end solutions, from design to cleanroom installation and commissioning.

Contact Airkey today for a consultation and discover how our engineering expertise can bring your project to life. Website: www.airkeyx.com