Where the Science Leads: Low-concentration VPHP

Are high-concentration applications the most efficacious way to use hydrogen peroxide for isolator decontamination? Is it possible to achieve 6-log reduction without common operational obstacles like extended outgassing periods, overwetting, heating and microclimates, and hazmat procedures?

AST and CURIS System have partnered to provide a rigorously tested and validated 7 percent VPHP solution for drug product manufacturing. The innovative decontamination system features one-touch automation and uses significantly less sterilant per cycle than traditional technologies—maintaining optimal decontaminant levels to execute a full cycle in as quickly as 1 hour. The groundbreaking solution is backed by multiple independent studies and is the only 7 percent VPHP system on the market approved as a sporicidal by the EPA through a tri-part soil load.

While conventional approaches utilising 35 percent or higher H2O2 concentrations maintain sterility, they often cost vital production time either due to speed-of-process or necessary safety measures for personnel and hazmat procedures. This advancement from AST and CURIS offers pharmaceutical manufacturers a proven time-to-market solution designed to meet the regulatory and production demands of the latest biopharmaceuticals.

HHP™ Decontamination for Cleanrooms (LS.CLNRM)

Biodecontamination of Cleanrooms using Hybrid Hydrogen Peroxide™ Technology

Traditional cleanroom decontamination processes include multiple steps and are wrought with opportunity for potential contamination, and legacy gaseous decontamination systems, such as vaporous hydrogen peroxide (vHP) and chlorine dioxide (Cl02), employ high-consequence, high-concentration chemicals that can pose risks to staff, leave residues, or damage surfaces. To overcome many of these difficulties, CURIS tested to see if its 7% hydrogen peroxide system could provide a 6-log repeatable reduction (sporicidal disinfection) on all cleanroom surfaces, as well as within filters. Request this study to see results.

CURIS is a full-service biodecontamination company, offering a complete suite of biodecontamination solutions to meet a broad range of your facility needs.

CURIS’s patented 7 percent VPHP

See how CURIS’s patented 7 percent VPHP solutions compare with legacy decontamination gaseous systems, including high-concentration hydrogen peroxide and chlorine dioxide, in achieving 6-log repeatable reduction.

How 7% VPHP achieves 6-log reduction:

What the latest science identifies and the groundbreaking work from CURIS confirms is that the key to VPHP decontamination is the micro-condensation process.

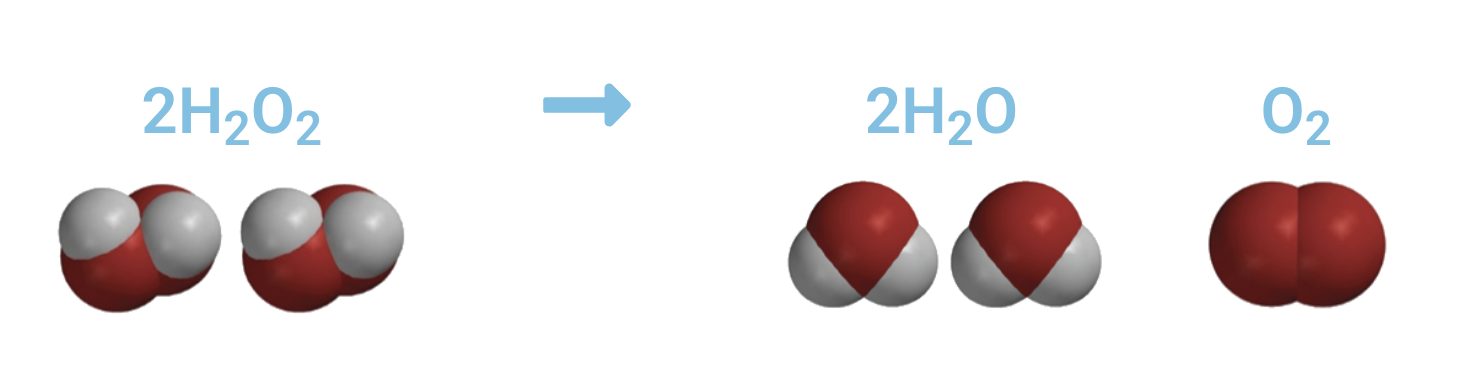

As H202 breaks down, this process of decomposition and oxidation releases energy that destroys cells, DNA, and microbials, and is the primary mechanism of decontamination.

The closer to the surface oxidation occurs, the more effective hydrogen peroxide becomes. Micro-condensation of H2O2 happens at a lower vapour point than water, ensuring that micro-droplets deliver an efficacious dose of hydrogen peroxide. For the best repeatable outcomes, H2O2 droplets should be as small as possible, in the sub-micron range (optimally 0.5-3 microns).

CURIS System’s 7000ei applies 7% VPHP evenly, rapidly, and consistently on all surfaces within the isolated environment, using automated feedback to maintain optimal kill levels with minimal amounts of H2O2 solution. The precise, controlled use of micro-condensation at particle sizes of 0.5-3 microns achieves 6-log reduction at a low-concentration VPHP application, drastically reducing cycle times and outgassing.