Profile

OUR SOLUTIONS

Microsphere formulation

Decades of experience in aseptic manufacturing has led PSL to develop the unique MicroSphere Refiner (MSR™) range for efficient microsphere formulation from small-scale processes up to commercial production.

MSR™ process technology is disrupting the way microsphere drugs are traditionally developed and manufactured around the world. Polymeric microspheres are ideal vehicles for many controlled delivery applications due to their ability to encapsulate a variety of drugs, biocompatibility, high bioavailability and sustained drug release characteristics.

This innovative technology addresses ongoing manufacturing challenges encountered by professionals working on synthetic polymers (PLGA, PEG, Hydrogel, etc.) such as size classification, efficient filtration (no mesh blocking), homogeneous drying, aseptic recovery of product and direct process scale-up.

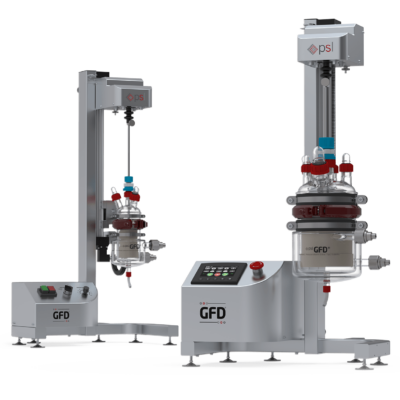

Filter Dryer Systems

PSL is a centre of engineering excellence in the design and manufacture of filter dryer systems used in sectors such as pharmaceuticals and fine chemicals. Our Agitated Nutsche Filter Dryers (ANFD) are renowned for their quality design and range from R&D activities, to pilot, up to commercial production.

Our filtration and drying solutions help maintain key process objectives such as product quality, product yield, batch consistency and key production parameters such as filtration time, washing time, drying time etc.

Our filter dryers provide optimum levels of safety and quality and can be manufactured to comply with various industry practices (cGMP, GAMP, etc.), directives (ATEX, etc.), regulations (21 CFR Part 11, etc.) and initiatives (PAT, etc.) from industry regulators such as the FDA.

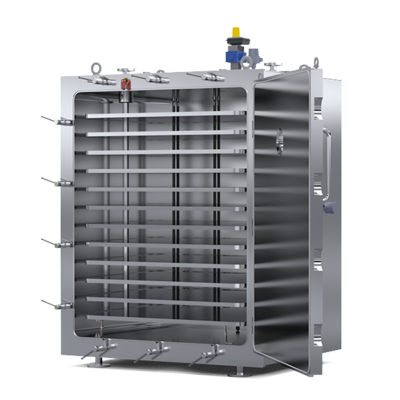

Vacuum Tray Dryers

PSL’s CakeStand™ vacuum tray dryer technology is predominantly used for pharmaceutical processes and products and remains an essential method with processes/products that are delicate or fragile when exposed to mechanical forces. It comprises a fully sealed vacuum chamber and direct heating shelves for optimum drying conditions and uniformity.

CakeStand™ is cGMP compliant and engineered to provide heat uniformity, batch reproducibility and data recording with an optional software and automation package. Due to the manual loading and unloading of product trays, in the case of moving potent and/or toxic products, PSL tray dryers can operate in downflow booths, clean rooms or in conjunction with PSL containment isolators.