The construction of a new pharmacy facility within a South West England Hospital Trust commenced in 2015 with a view to transforming the estates and improving the patient services provided. The building was designed to ensure the latest high standards for the safe preparation and storage of medicines. It has been located closer to key clinical areas, such as the new Cancer Centre, intensive care for adults and children and a number of key surgical and medical wards, ensuring a better, more efficient service to patients.

The facility also provides medicines for all inpatients on-site as well as a range of community hospitals. It is supported by an outpatient dispensary in the main entrance of the hospital.

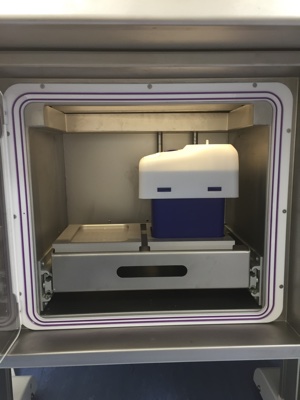

A cytotoxic isolator

Highly-specialised medicines are prepared daily in the new pharmacy, including chemotherapy drugs and a range of radiopharmaceuticals used to help diagnose many conditions. The building also includes a new aseptic unit, where cancer and other medicines are prepared in sterile conditions.

Cirrus Containments was awarded a contract for five new isolators. The remit was to provide quality isolator units that would fit into the new, contemporary building and fully meet the specification issued by the Trust. The isolator units would be located within the radio-pharmaceutical and aseptic areas.

A mAbs isolator

The following units were specified:

- Two aseptic Cytotoxic isolators

- One mAbs (Monoclonal antibodies) isolator

- One Blood Labelling isolator

- One Tc99 Elution isolator

The Trust had specific requirements to future proof the facility from an IT perspective and to align with current and pending regulations which resulted in all isolators being linked to the IT network. This has enabled Cirrus Containments to provide an offsite fault diagnosis service remotely connecting to the isolators to rapidly diagnose any issues which can save multiple service support visits and reduce down time.

One of our challenges was to reduce the volume of extracted air. The isolators were all specified as unidirectional, which would traditionally require a high-volume fan per unit extracting approximately 600m³/hour via an external stack. Power consumption and AHU specification dictated that this was not going to be feasible.

The solution was to offer a partially extracted alternative where 90% of the air within the isolator is recirculated with just 10% externally extracted. Significant power consumption savings can be achieved with this system as the isolator on-board fans can be finely tuned and controlled further increasing efficiency. The small volume of extracted air resolves issues with overheated air and high humidity levels which can arise if the extracted airflow volume is too low. This system was adopted and very successfully implemented resulting in a very small total volume of exhausted air into the environment.

Ergonomic construction

Ergonomics must always be carefully considered when designing equipment for long term use. The Pharmacy team had to ensure that the new isolators were going to be suitable to use for the entire team to operate comfortably, either standing or seated operation.

All internal surfaces had to be easily accessible for cleaning without the use of extension tools and without the need to stretch to reach difficult areas. To achieve this the isolator height could be electrically adjusted via the HMI screen (including the Tc99 INCUS isolator weighing over 800kg), with comfortable foot rest position and lower filter guarding to protect operators’ knees. Back injuries are prevalent due to poor posture within this pharmacy environment. However, selection of multi angle height adjustable chairs, isolator height adjustment and sloping front screen on each isolator helps to minimise this problem.

Rear touch data screens

The Trust was keen to integrate touch screen technology within the isolators to ensure the capability for electronic document management systems was included. The screens are fully sealed and mounted to the back panel within the isolator processing module. This removes the need for hard copies of documents such as procedures and protocols for electronic data management. A major benefit is document control, which significantly reduces accidental use of outdated documents.

The screen is a Projected Capacitive touch, which means it can be activated when wearing surgical gloves and it enables multi-touch, similar in operation to a smart phone. An integrated PC enables the screen to be connected to the network, ideal for two-way data flow between the Pharmacy office and isolator operator and essential for interactive training.

Another major benefit of rear screens is the integration with smart chamber dose calibrators. These now no longer require a remote display unit as the data can be displayed directly onto the rear screen. The chambers connect directly to the network infrastructure so that display can be viewed from any PC (remote viewing) process.

The INCUS Tc99 Elution isolator is larger than the company’s standard isolator, consisting of a 4-glove processing module, a 2-glove elution module with integral 65mm thick lead shielded store capable of fully shielding two Alliance Generators and a single Transfer module.

inside view of Alliance Generator within the T99 isolator shielded storage module

To provide additional protection to the operators, a hidden lead skin was added to the lower surfaces and the glove panels, manufactured from H35 lead acrylic.

The isolator was constructed in two sections to get it into the radio pharmacy cleanroom, then re-assembled and SAT tested. The Elution process is assisted by a fully automatic generator positioning system, which retracts the storage module upper shield and raises the generator to a position that is perfect for eluting while offering maximum operator protection.

Part of the installation and commissioning process is Leak Testing. This is an important aspect of commissioning and must be demonstrated on a regular basis when in general operation. Each module must be verified to be within the defined limits at SAT level before approval. Following SAT sign-off, IQ and OQ tests were undertaken and DOP testing completed before pharmacy staff could finally begin the PQ process.

On 2 May 2017, the new pharmacy was finally complete, with all staff moved in to the state-of-the-art building.