Multiplexing air samples from various sample points into a single particle counter offers the ability to monitor small particle sizes at a reasonable cost. Using a multiplexed system, also called a manifold system, one can monitor 0.1µm particles with a 1 CFM sample rate for about the same cost per point as using continuous monitors at 0.3µm with 0.1 CFM sample rate. The combination of higher sensitivity and higher sample volume provide much better data while the system is sampling from a particular location.

Additional cost savings can be realised using the multiplexed system if lower sensitivity is acceptable. The disadvantage is the duty cycle is less than 100% at any particular location, so it is possible to miss episodic or time-dependent events.

Two common concerns about manifold systems are particle loss during transport, through the tubing, or significant delays in particles reaching the particle counter. Successful transport of sample air through tubing necessitates both a thoughtful design and care in installation.

To assure successful transport, PMS uses a noncontaminating valveless design that eliminates the need to purge between samples and improves the sampling duty cycle. Other key parameters that must be controlled are transport velocity, turbulent flow, tubing bend radius, triboelectric charging, and isokinetic sampling.

It is generally accepted that a Reynolds number of 2200 is the minimum required for turbulent flow. This corresponds to about 1 CFM flow in tubing of 3/8" internal diameter, which is the PMS standard ID.

There are several different PMS manifolds to select from that have the capabilities of monitoring up to 30 locations with a single particle counter or up to 500 locations with a combination. The PMS manifold models to select from are the AM-12, AM-24, and the AM-30. These manifolds will pull 3 CFM through all tubes simultaneously, with a maximum recommended length of 125 feet.

The length of time it takes for a sample to travel from the sensor to the particle counter is dependent on both the tube’s material and length. Based on general experience, tubing choice is in this order:

-

No. 1 - Stainless steel

No. 2 – Bev-a-line

No. 3 - Polyester (as polyurethane)

No. 4 – Polyester-lined vinyl

No. 5 - Copper

No. 6 - High density polyethylene

No. 7 - Glass

No. 8 - Teflon

It is important to note that the desirability decreases as bulk resistivity increases. Plasticised PVC (Tygon) is not generally recommended because of its slow plasticiser release to the environment. Selection of smaller tubing for the longer lengths is a viable option; however, the pressure drop increases with decreased diameter.

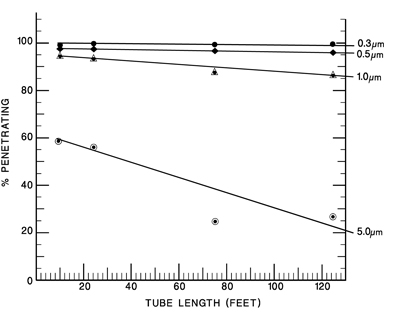

The amount of time it takes a sample to reach the particle counter at various lengths and flow rates through basic calculation, using the PMS standard 3/8” inner diameter tubing, is shown in Figure 1. Note that losses for particle sizes less than 1µm are negligible. For 5µm particles, losses are appreciable.

Figure 2: Particle loss rates in Bev-a-line XX tubing, 3/8 I.D., using PMS 3 CFM aerosol manifold flow rate

PMS conducted a test using the AM-12 manifold with a Siemens’ vacuum pump to determine particle loss in 3/8" ID Bev-a-line tubing. Lengths of 10 feet, 25 feet, 75 feet and 125 feet were connected to the manifold. A particle counter was used to sample the air at the tubing input point and at the output of the AM-12 manifold. The results are shown in Figure 2 for four particle sizes.