You may think using a risk-based particle sampling decision tree, “Now you can sample particles!”

Of course, it is not that simple!

First things first, even if the new technical report, ISO/TR 14644-21 provides a guide on proper particle sampling techniques, both for cleanroom classification and for monitoring, we should not expect it to reduce our risk on its own.

As mentioned, this is a "Technical Report", not a standard, prepared by Subject Matter Experts with an intensive knowledge of the field and applications.

Let's take a look at it and see what we should expect from this new ISO/TR 14644-21 Technical Report and what we should not.

What is this Technical Report for? Is it a new standard?

This is not a new standard but a Technical Report (ISO/TR) that provides clarification on the application of sound airborne particle sampling techniques in support of ISO 14644-1:2015 for the classification of cleanrooms and clean zones, and ISO 14644-2:2015 for airborne particle monitoring, to provide evidence of cleanroom performance related to air cleanliness by particle concentration.

It provides information on how to gather appropriate, accurate, and repeatable data, and how to interpret this information to improve process protection.

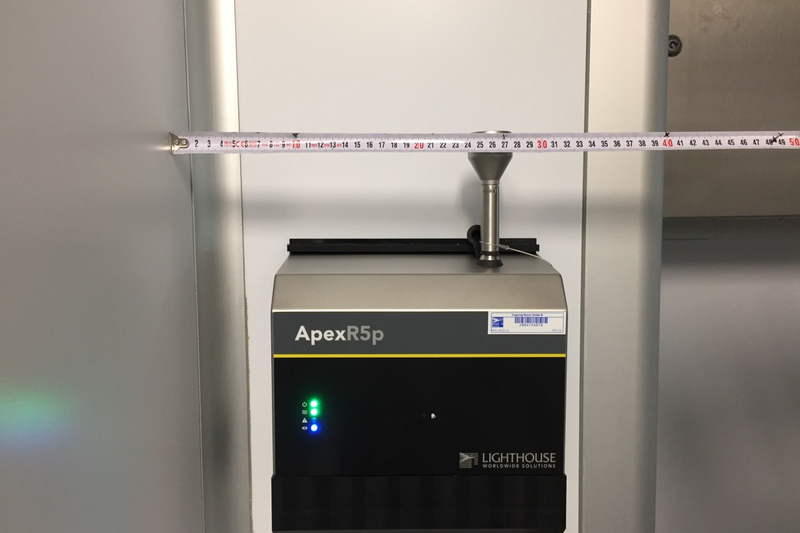

Most people misinterpret ISO 14644-1:2015 Annex C 4.1.2, one-meter sampling tube limitation.

This was for macroparticles in cleanroom classification applications. We have seen many applications that are trying to implement this change to their cleanroom monitoring design.

Keeping the sampling tube distance as short as possible is the best approach for sure. However, this limitation, when applied to all monitoring locations, can bring another risk or wrong system implementation that will endanger sampling quality and even the particle counters.

So, the Technical Report ISO/TR 14644-21 addresses this in a unique way; with a "Decision Tree”.

This decision tree will guide you on sampling challenges and how to overcome them by adding another level of control and verification.

As per the introduction section of this new ISO TR, ISO/TR 14644-21 addresses the importance of understanding that:

- For classification, the quality of the sample is the most important factor

- For monitoring, the quality of the data is the most important factor

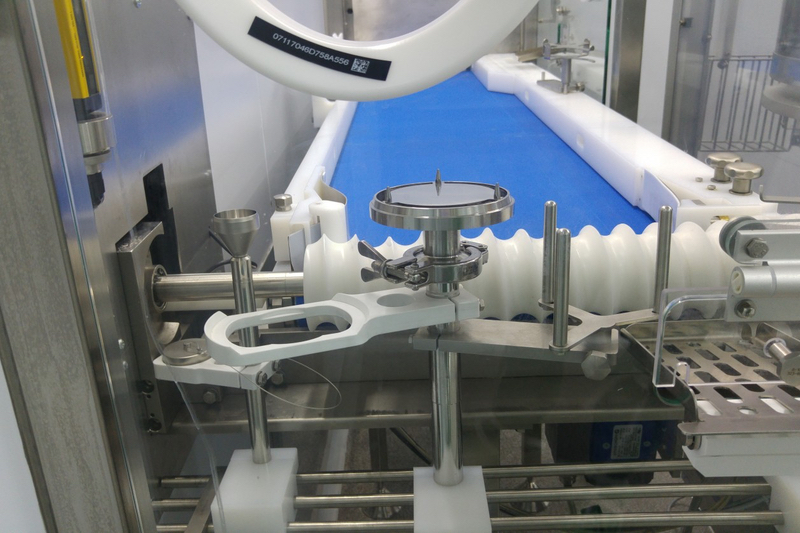

- Direct sampling without tubing is preferred. However, sample tubing is sometimes necessary to get a representative sample at a significant or critical location

- To reduce sampling loss in tubing, this tubing is as short and straight as possible

- A sampling system is evaluated to assess the impact of any compromises in its setup

What are the sections of ISO/TR 14644-21 Particle Sampling Techniques

Apart from general content such as scope, terms, and definitions, below details the sections and summary of each.

Determination of airborne particle concentration: This section has a nice and smooth explanation of airborne particles, cleanroom particle classification, continuous monitoring, and their common parts and differences. Cleanroom classification as establishing control and monitoring as demonstrating it, everything within these two very important activities has a detailed explanation here.

Sampling airborne particles – things to consider: We all know, the best approach is to place our portable or fixed/online particle counter at the risk location, without an additional sampling tube. However in real life, due to the several limitations, this is not always possible or even practical.

So this chapter covers several aspects regarding the sampling tubes, distances, tube radii, no of bends to reach from sensor locations to the final risk point and the bending radii, etc.

Apart from particle counter selection, sample location considerations, and instrument measurement issues, the heart of the Technical Report is also located in this section; the Decision Tree.

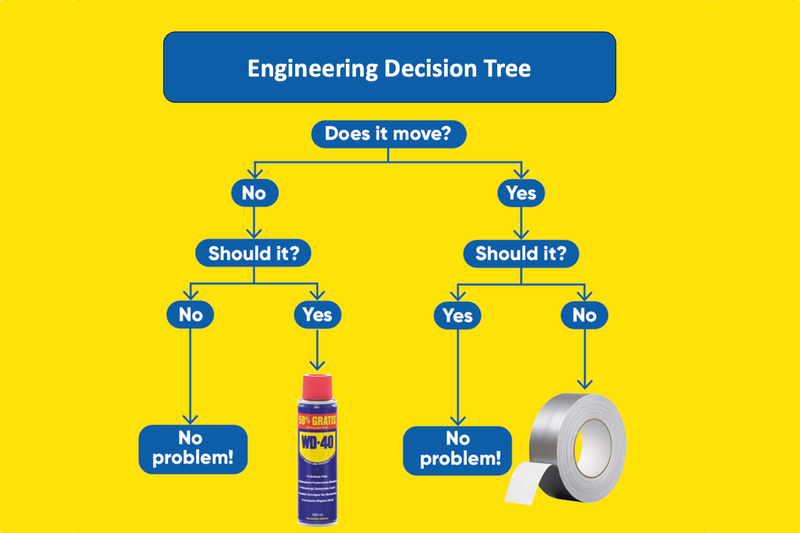

What is this "Decision Tree" all about?: To consider particle loss and determine the suitable sampling of airborne particles can be evaluated using the concept of a "decision tree"

Have you ever seen the duct tape and VD40 decision tree before? (Image below) Consider this the same but more sophisticated and scientific-based.

The decision tree for sampling challenges and potential solutions is quite similar to this one, but more scientific-based for sure!

There are 4 stages in this decision tree:

- Probe Orientation? Simply, can you sample without a tube, with a direct mount isoprobe to your particle counter? If so, please go ahead and do it. If not move to stage #2.

- So, you need sample tubing. Sample Tube Length is a challenge. There could be several reasons; area limitations, installation challenges, risks for locating the particle counter directly at the sampling point, etc. Whatever it is, if you are sampling smaller than 5 microns, your risk will be less. That's what we know from scientific experiments. Even with a longer distance like up to 3 meters (of course number of bends, tube radius, bending radii, etc. will affect, we will come later on). If you sample 5-micron particles, then there are additional risks to be considered. Try to keep it less than 1 meter then. If not, the decision tree will guide you to another level of risk.

- Tube Bedings. The number of bends and their radius are critical here. The decision tree will now guide you to the Top 2 risk considerations at our final level; decision.

- Decision. Depending on your risk level, the decision tree ends up at 3 different levels.

The three outcome options

A) No Assessment Performed: If you can sample particles with direct mount isoprobes to your particle counter or your targeted particle sizes are smaller than 5 microns, or less than a 1-meter sampling tube with less than 2 bends are considered, you are safe. No additional assessment is needed. Particle losses in these applications have a low impact on measurement quality.

B) Additional Assessment Considered: For example, if your sampling location has less than 2 meters of sampling tube and/or with less than 3 bendings for example on sampling tubing, there are additional assessments that you should consider. Particle losses in these applications can affect the quality of measurement. Additional information is sought to understand the impact of the effects.

C) Additional Assessment Performed: Now we have trouble here. Our sampling system design requires more attention than any usual system design. We may have more than 2 meters of sampling tubes with more than 2 bendings. This requires a certain assessment of your system. Particle losses in these applications can affect the quality of measurement. A review of the system installation is performed to fully evaluate the impact of particle losses.

What are these additional assessments?

Now we know our risk level but what to do and / or consider to reduce it. This is what the decision tree discusses in the example section. There are certain aspects to be considered to reduce your risk and generate more reliable data to ensure your data quality. The list below show some examples.

Tube diameter: Using larger tubes at longer distances can help you pull the particles with a less losses

Using the right type of sampling conduit like stainless-steel tubing will help you to keep the bending radius fixed as well as reduce your risk of the peak due to shaking and unwanted contact with the naked sampling tube.

Using the special installation fixture will help you reduce your risk and can even shorten your distance and reduce your number of bends.

Perform an engineering study to compare your data with an isoprobe directly mounted to the particle counter vs. your current challenging sampling structure. This will show you your risk level and you may review/update your alarm and action levels considering the percentage of loss due to the sampling system you have installed.

How can I download the ISO/TR 14644-21?

You can visit the ISO portal online. Unfortunately, it is not a free document and like other ISO documents you have to pay and download an electronic copy.