Best practice for both wipes and mops in a cleanroom environment is to use single-use disposable products: they reduce the risk of cross-contamination and ensures that contaminants are physically removed from the production space at the end of a session. However, more and more facilities are laundering and re-using mops as a potential cost-saving alternative.

Most reusable cleanroom mops, however, are manufactured from microfibre yarns, a material that is known to have properties that make it good for a cleaning tool, but also make the tool nearly impossible to be cleaned.

Even the smallest cleanroom facility will spend tens of thousands of pounds on cleanroom consumables in a year. In a large facility, the figure reaches hundreds of thousands easily. Therefore, careful consideration needs to be given as to whether the reuse of mops, especially those made of microfibre, can lead to a reduction in consumable quality, which could subsequently lead to contamination of a final product or a reduction in yield.

Microfibre under the microscope

Microfibre was introduced in the late eighties. It was defined as a fibre with less than one decitex per filament. Decitex is a measure of linear density commonly used to describe the size of a filament or fibre. One decitex is 9/10th of a denier. To put this into perspective, a microfibre is 1/16th the diameter of a human hair.

Microfibre can be combined to create yarn, which can be knitted or woven into a variety of constructions. Microfibre fabrics can be broken down into two main types: splitable and straight filament.

Straight filament microfibre tends to be made from 100% polyester while splitable microfibre consists of very fine threads of polyester and polyamide (nylon) that are combined to form a single thread. The nylon is used to glue the fibres together until they are split later in the process.

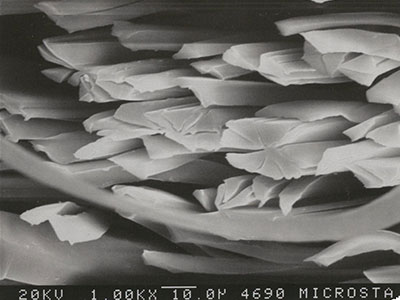

Figure 1

Split microfibre possesses numerous wedges rather than the rounded threads found in other yarns (see Figure 1). It is these wedges that provide the ability to collect microscopic particles off a surface. The expanded surface area, and the capillary action of the fine threads, dramatically increases a microfibre wipes sorbancy. A change in the percentage of the microfibre blend will yield slightly different properties.

This split structure gives the wipe the ability to pick up particles, even when dry, and can easily remove residues often without solvent.

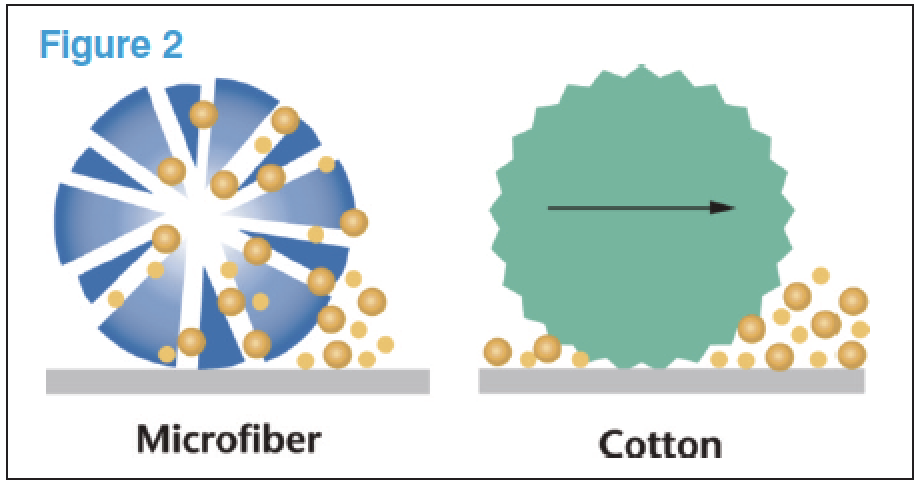

As illustrated in Figure 2, the split fibres create microscopic spaces that collect and hold dust, dirt and particles more effectively than rounded fibres such as cotton.

Furthermore, microfibres are positively charged; they attract the negatively charged dirt electrostatically. Microfibre has a high sorptive capacity, around six to eight times its own weight in water. The fast wicking ability means a wipe can remove spills quickly and easily, so it is very suitable for mop to dry situations.

Microfibre mops in the cleanroom

Their high level of sorbency and ability to pick up and keep small particles has led to the increased use of microfibre mops in clean production environments. However, microfibres are less durable than standard filaments and create much higher levels of fine particle contamination.

To reduce these contamination levels, hence to be suitable for use in the cleanroom, microfibre needs to initially be laundered. This processing, coupled with the cost of the microfibre yarn itself, means most cleanroom microfibre mops are too costly for single use. They need to be laundered, resterilised and re-used to be a cost-effective option.

Typically, this process involves a contract with an external industrial laundry, and if a sterile product is required, either an autoclave or irradiation provider also comes to play.

The laundry paradox

The process of relaundering, and the resterilisation of cleanroom mops, is not without risk. Laundries use mechanical, thermal and chemical processes in washing and drying that can cause irreversible damage to the delicate microfibre structure. It can lead to a mop or wipe degrading over time and affecting both its cleaning ability and sorbent capacity.

The laundry facility is left with a paradox: either subject the products to effective laundry conditions that damage the cleaning efficiency of the fibres or protect the products from degradation by minimising the harshness of laundry treatment conditions

The fine filaments and delicate fibre structure are designed to gather and hold dirt, organic matter and microbes, so it is extremely challenging to consistently remove those contaminants in each successive laundry cycle. The laundry facility is left with a paradox: either subject the products to effective laundry conditions that damage the cleaning efficiency of the fibres or protect the products from degradation by minimising the harshness of laundry treatment conditions, hence risk incomplete cleaning and disinfection of the mop.

The Healthcare team at Contec investigated this paradox in more detail and published their findings in the white paper Clinical Advantages of Disposable Microfibre Mops. The study compared hospital relaundered microfibre mops with a disposable microfibre product.

Microfibre mops were examined microscopically before and after laundering to visualise the impact of the process. The levels of organic and inorganic residues trapped in the microfibre structure were examined microscopically before and after relaundering: the impact of the residual organics on subsequent quaternary ammonium disinfectants (quat) binding was determined, the bioburden on the mops after laundering was quantified, and the actual cleaning efficacy of the relaundered mop versus a disposable mop was quantified in a patient room using ATP analysis.

Although the parameters in the study are not all directly applicable to clean production environments such as cleanrooms, especially in terms of bioburden collected, some findings are relevant and should be considered.

Visual and microscopic analysis

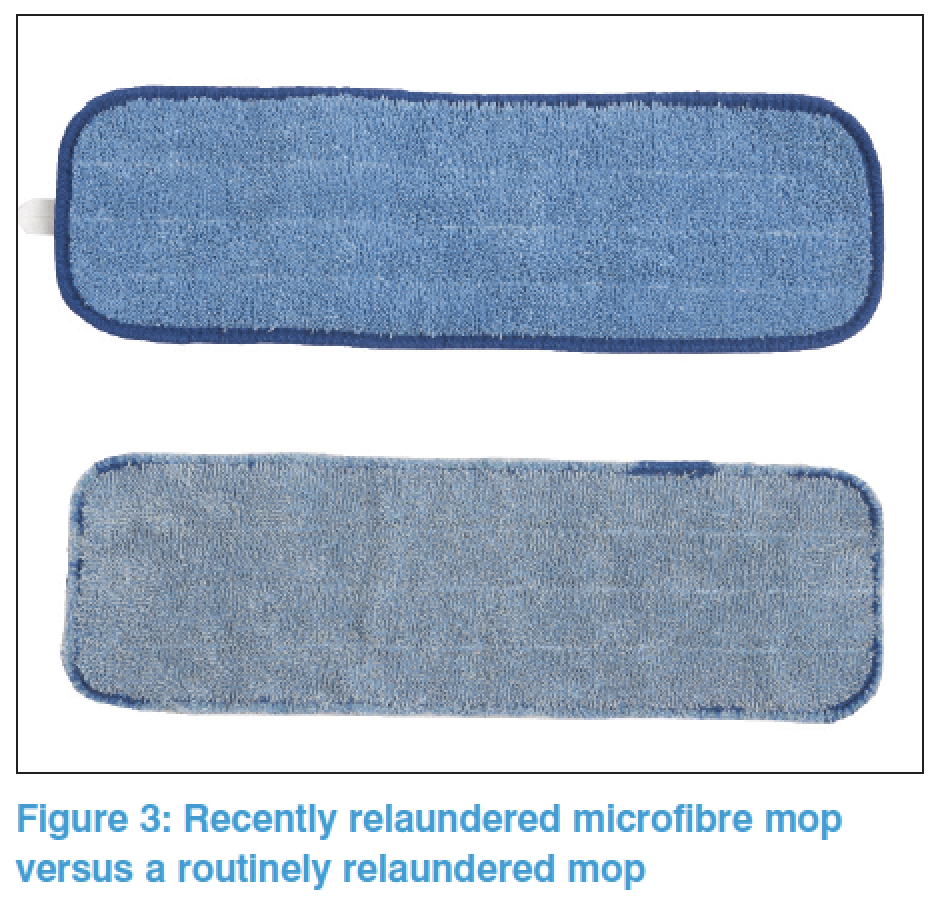

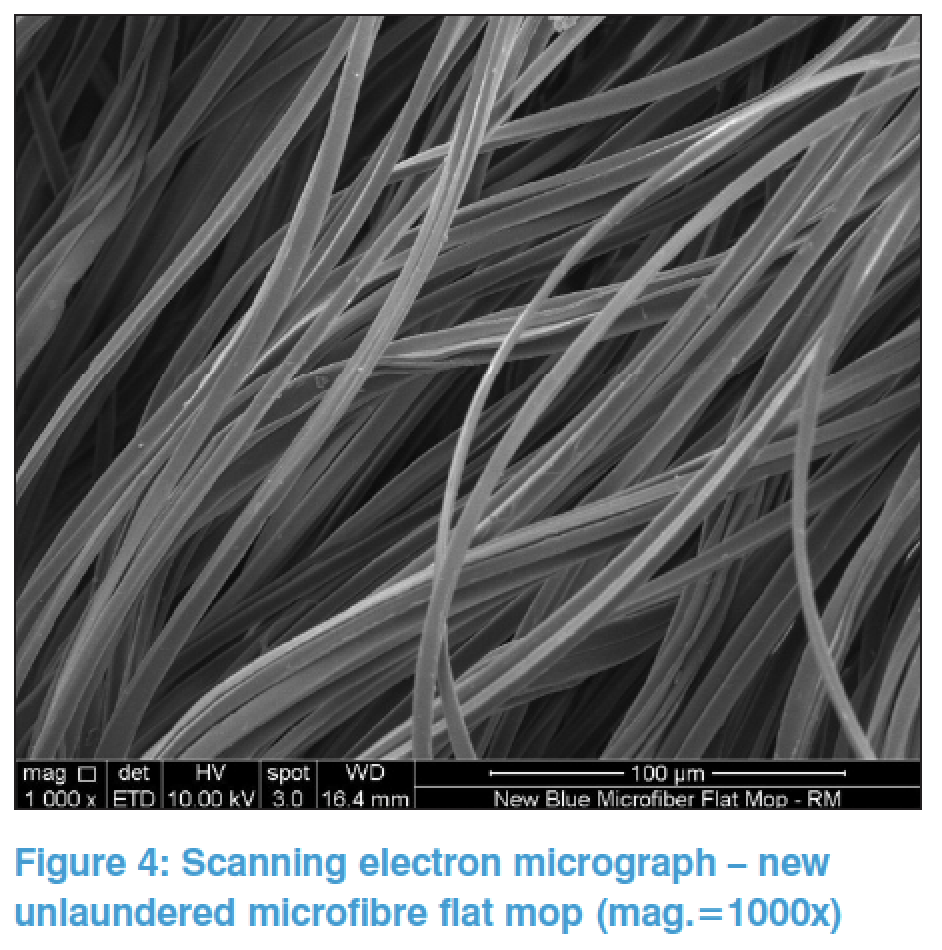

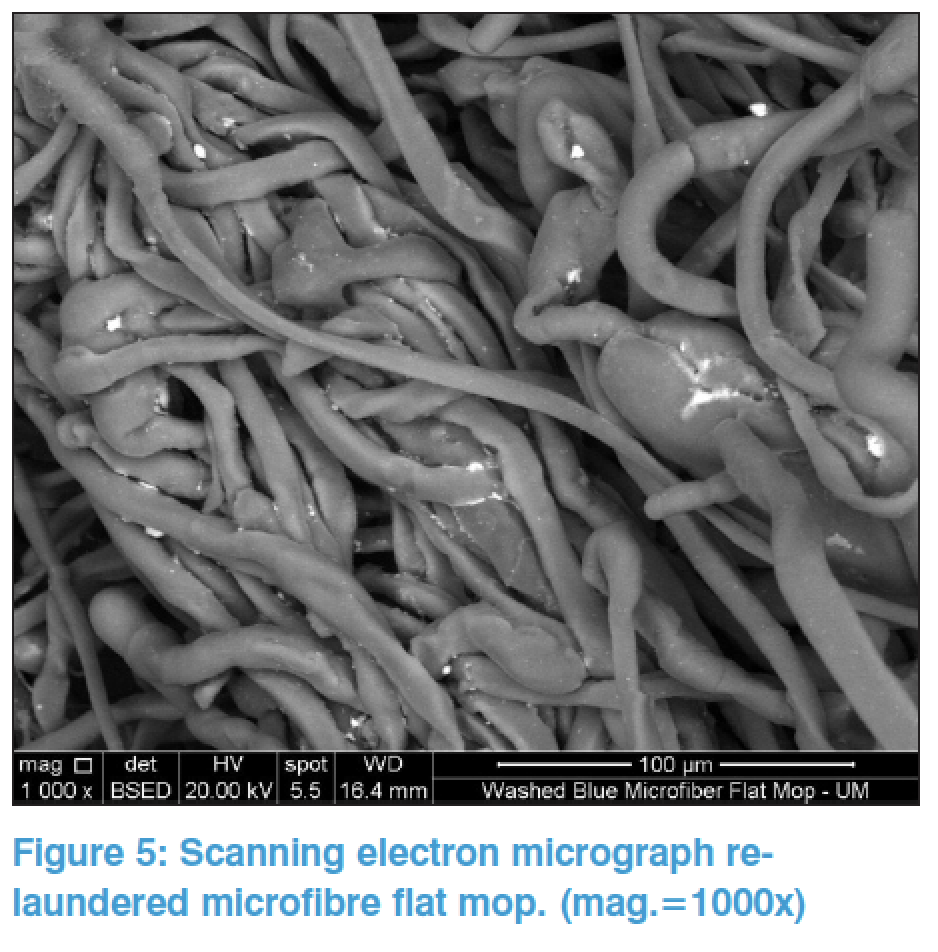

The effects of repeated laundering can sometimes be obvious to the naked eye, especially with coloured mops (see Figure 3). This visual degradation would be picked up if the customer has specified a rigorous inspection routine for the mops as they go through the relaundering process. However, the scanning electron microscope analysis highlighted the unseen damage that is occurring. Figure 4 and 5 show the dramatic difference between “new” microfibre and microfibre that had been “in the system” for just a few laundry cycles. Clearly, the fine nature of the synthetic microfibre make them susceptible to damage and the harsh laundering process, with chemicals, heat and abrasion playing a part in the cleaning and drying process. The laundered fibres appear distorted and melted together and this can result in decreased performance in terms of sorbency and ability to hold particles and microbes. Particulate contamination not removed by laundering (or introduced during the laundering process) are evident as white specks in Figure 5.

Residues in the mops

The study proved that is possible that the laundry process is ineffective in removing trapped residues of the disinfectant or detergent solution. This can be easily measured be soaking the mop in clean water and then squeezing the extract into a clear, clean beaker. If the resulting water is dirty, cloudy or contains suds then the laundry process has failed to sufficiently remove all the trapped chemical residue.

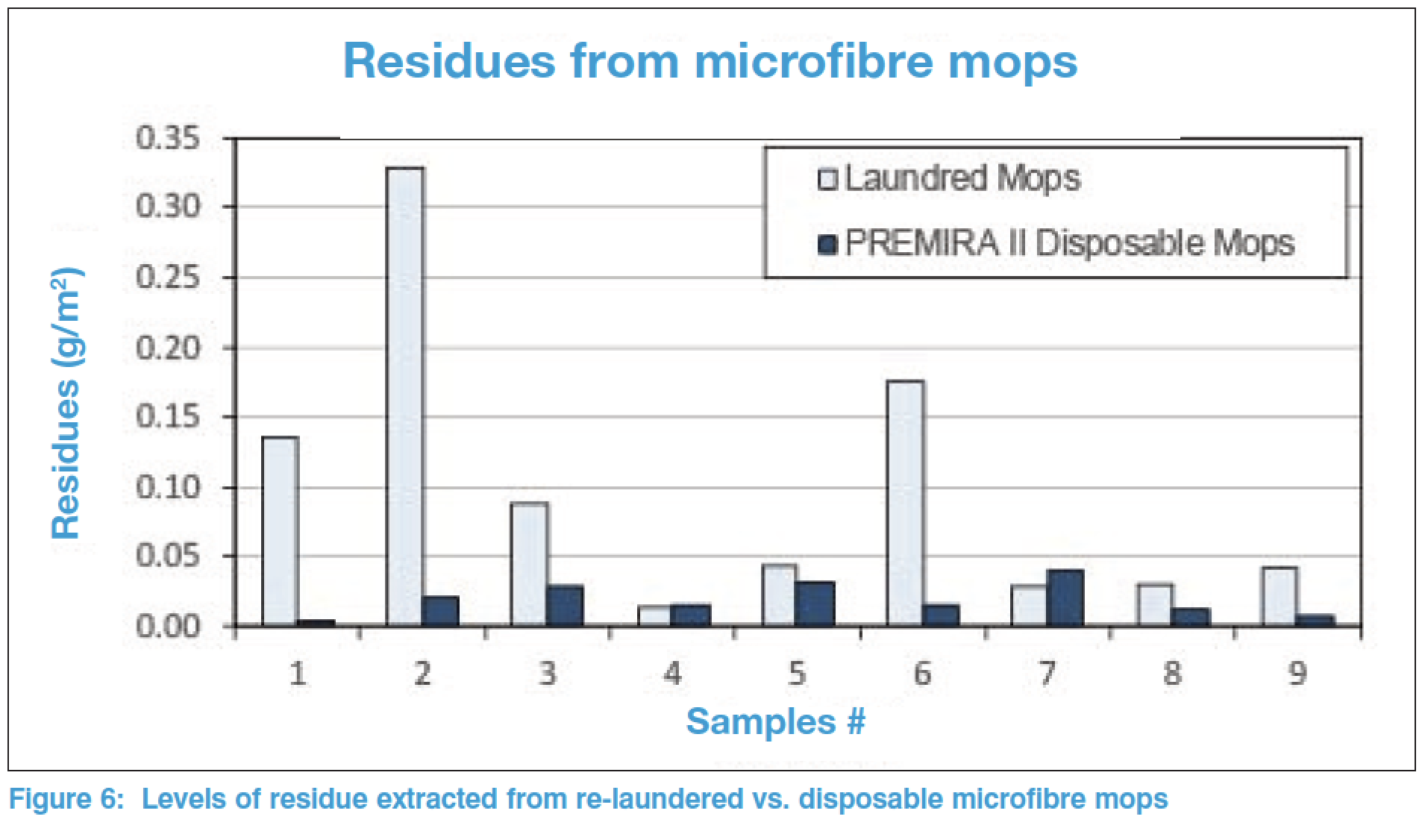

Using the recommended practice, published by the Institute of Environmental Sciences and Technology, an extraction test was conducted on 18 samples (nine laundered re-usable microfibre mops and nine new Premira II microfibre pads) to compare residuals from laundered re-usable mops versus disposable mop pads. Samples of each mop were taken only from the microfibre fabric portion. Results of the analysis for residues are shown in Figure 6.

The laundered microfibre mops had an average residual level of 0.099 ± 0.102 gm-2 whereas the average residues from disposable microfibre mops were nearly five times lower (0.020 ± 0.012 gm-2) and exhibited much lower variability among the nine samples.

The retention of organic particulates and residues in laundered mops can cause issues when the mops are returned into use. Disinfectants and sporicides are very reactive and can either readily bind to organic materials or be deactivated by them, whether they are living or not.

If the mop head is contaminated with residual detergents or organic debris left over after laundering, the mop head itself can bind or inactivate the disinfectant chemistry before it ever touches the surface to be disinfected. Examples of a similar reaction have been demonstrated in previous studies where quats readily bind to cotton-based (cellulose) cleaning wipes and mops. This type of reaction can also occur with the residual organics in laundered synthetic mop heads.

Disinfectant dilution

To quantify this binding effect, the study compared laundered disposable microfibre mops with a common quat-based disinfectant. Both mops were immersed in a 1,000ppm commercially available quat solution for 0.5 to 60 minutes. After removing the mops, the residual amount of active disinfectant on the mop as well as the amount of active disinfectant applied to a prepared surface. Not unsurprisingly, the level of active disinfectant available decreased by 20% within the first minute of exposure to a laundered microfibre mop.

More interesting, the concentrations in solution continued to decrease with the longer exposure times: within 15 minutes, the levels in solution contacting the mop had dropped below the level required for effective disinfection.

With the disposable microfibre mop, the level of active quat in solution also decreased during initial exposure to the mop. However, unlike the laundered product, the concentration of active disinfectant stabilised after one minute and remained at effective levels throughout the duration of the study.

The levels of active quat recovered from the stainless-steel coupons were lower than the levels from the mops, but the same trends were observed between disposable and laundered mops.

These results indicate that residual organic matter can impact the efficacy of disinfectants when applied with relaundered microfibre mops.

Process validation

The use of disposable mops is very straightforward: a new mop is used to clean a specified area, then downgraded for use in less critical areas, or discarded outright after the primary use.

The surface area cleaned per mop is determined by sampling of critical metrics and validated if the area is sterile.

The number of particles and fibres shed by the mop is assessed using by laboratory work provided by the manufacturer. The ability of the mop to apply a validated disinfectant for a validated contact time is assessed and documented. The same initial testing and validation is carried out for a reusable mop.

Since disposable mops are made from new materials to a validated process they provide a consistent and predictable performance and result, even over a long period of time, as a new mop with the same parameters is used. As shown by the study, the effect relaundering has on a microfibre mop can lead to the performance and quality of the mop changing over time due to the inevitable degradation of the reused mop.

For the evaluation of a reusable mop project, it is necessary to predict the performance and quality over time to estimate the lifecycle and related costs of the mops. As the actual quality, contamination profile and performance of reusable mops will deviate over time, such deviation could result in an unintended, and potentially unacceptable, risk to the customer’s environment and the product.

Understanding the real risk of using reusable mops can only be accomplished through repeated periodic revalidation over the period of relaundering and the costs for that repeated validation factored in.

The decision on whether to use disposable versus laundered reusable mops may boil down to a simple, yet fundamental question: “Do you really know the mop you’re using?”

N.B. The author would like to acknowledge the input of Pier de Jong and David Nobile from Contec’s Technical Service Dept in the creation of this article.

This article is featured in the December 2018 issue of Cleanroom Technology. The digital edition is available online.