AES Clean Technology has more than 35 years of cleanroom construction experience and has been a pioneer in modular cleanroom construction for more than 20 years. As a result, our pre-engineered, configurable, and custom solutions represent decades of know-how and continued improvement. We have learned a lot during this journey.

About Modular

In modular construction, wall and ceiling panels are manufactured in a factory, flat packed for shipment, delivered to site, and then assembled, much like LEGO building blocks. AES wall and ceiling panels are manufactured with an aluminum honeycomb core under heavy sheet metal covered with a durable uPVC coating. A few manufacturers mimic this construction. Still others eliminate or substitute materials to cut costs.

Regardless of manufacturing method, one of the most important considerations in pharmaceutical cleanroom applications is that materials used are non-absorptive, non-shedding, and non-reactive - this is required to ensure the safety, identity, strength, quality, and purity of the drug product ensuring that nothing that is not supposed to be present ends up in the product. Additionally, it is critical that materials selected can stand up to the intended use of the cleanroom.

About Stick Built

The primary alternative to modular is commonly called stick built construction, which generally involves construction of cleanroom spaces using metal-framed structure(the sticks) covered in gypsum wallboard. Stick built construction is often perceived as more affordable given the simplicity of the techniques involved and material costs, overall. Those perceptions, however, may not take account of long term durability and the associated costs of maintenance.

The Dirty Secret about Drywall

Any homeowner that does the least bit of work around the house knows some of the inherent advantages of drywall. For certain, drywall is cheap, easy to store, and simple to cut to any shape for any application.

While a skilled hand at drywall construction takes experience, any amateur can quickly cut a piece to patch a hole in the wall or repair a section of water-damaged ceiling. A few coats of joint compound and some light sanding yields a pleasingly smooth surface.

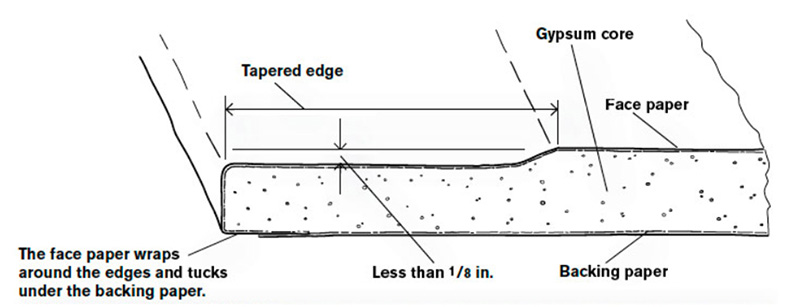

Any homeowner will also know the inherent disadvantages of drywall. It is messy to work with and easily absorbs and retains moisture. Drywall, after all, is a simple product made of gypsum rock sandwiched between sheets of paper. It crumbles when cut, and it swells when wet.

In damp environments, drywall becomes something far worse: a welcoming home to mold and other microorganisms. Gypsum naturally draws in and retains moisture, while the cellulose and starch used in drywall covering becomes, in essence, a growth medium for spores.

Mold growth is not just unsightly, it is potentially dangerous. Case in point, since the early 2000s several children have died due to exposure from a recurring mold infestation at one children’s hospital in Seattle. It is decidedly the opposite of a controllable environment.

Drywall is also less forgiving to harsh chemical cleaners and less tolerant of bumps and knocks.

Drywall Side View Image

Time Is On Your Side with Modular Installation

The other disadvantage to stick built construction is that everything is built on-site. That means introducing construction debris, dust and other foreign objects settling into your cleanroom environment. The end quality of stick built construction is inherently variable, mostly depending on the abilities of the craftsman who happens to be on site that day (again, ask any homeowner). On-site construction can also pose a risk to your timetable, particularly as builders jockey with other trades, such as plumbing or electric, for time on-site.

With modular installation, actual time at the work site is fairly limited, since everything has been pre-sighted for assembly.

At AES, we believe your clean environment begins on our manufacturing floor, and modular cleanroom installation is the fastest path to a productive, worry-free, and commissioned manufacturing space for your pharmaceuticals and biological materials.

I mentioned that there were some perceived advantages to stick built construction, mostly in regards to short term costs. In my next entry, I’ll explain how modular installation will show its value time and time again.

Faciliflex Modular Advantages:

- Modular is installed while drywall is built

- Modular is non-absorptive, non-shedding, and non-reactive while drywall absorbs moisture, is easily damaged and promotes microbial growth.

- Modular installation and renovation are inherently clean while stick built produces construction dust and the quality of product entirely depends on the skill of the builder.

- Modular is virtually maintenance free while stick built requires routine, ongoing maintenance.

About the Author:

Royce Tourtillott is Western Regional Sales Manager for AES clean technology. His primary focus is on helping Clients develop and realize their business goals without compromising patient safety. With nearly 30 years of progressive experience, Royce has developed new technologies and successfully grown high-tech businesses serving the life science industry. He is inspired by those working to improve the human condition and seeks to equip others with the best tools available to fulfill this mission. As a recovering mechanical engineer and hopeless nerd, Royce enjoys spending free time tinkering at his electronics bench, enjoying the outdoors and traveling with his wife and daughter.