As EU GMP and PIC/S Annex 1 sets out, poorly controlled cleanrooms will be more prone to microbial contamination compared with well-controlled facilities.

Assuming effective HVAC design, the primary routes of contamination are via people or via the transfer of materials.

Microbial-carrying particulate contamination will either remain suspended in the air (prior to its eventual removal through air extracts) or settle onto a surface.

This potential to transfer microorganisms from surface to surface exists as an often-present hazard for the cleanroom manager to contend with.

This contamination includes fungi, which present a particular concern in terms of spore dispersal, and which have been linked to many instances of product contamination.

The concern with standard flooring is that the disinfectants used to periodically treat the floor only have a short-lasting residual activity

One source of fungal contamination is either fungi present on the shoes worn by personnel or be deposited onto the floor area from airborne particles, through gravitational settling and other air current disturbances.

This presents a concern that arises through re-dispersal, where the subsequent activities of walking or pushing carts can either cause deposited particles to be resuspended in the air and contaminate whatever is moving through the space or become attached to the moving surfaces, including footwear.

Fungal challenges

The types of contamination present will include fungi (yeasts and moulds).

Fungi present a problem in pharmaceutical manufacturing due to the ability of fungal spores to travel across air currents; with fungi able to grow on a wide variety of substrates; and due to the risks from mycotoxins being produced within a product.

The study was conducted at a pharmaceutical facility in the south-east of England

Consequently, fungal contamination incidents make up a large proportion of pharmaceutical product recalls due to microbial contamination.

Although the types of external environmental fungi will vary geographically, there are some common genera found in most parts of the world (such as species of the filamentous fungi Aspergillus, Fusarium and Penicillium).

Some of the fungal sources will be from the external environment, some from the built environment, and some will arise from the human mycobiome.

Contamination solutions

For cleanroom managers the main options for seeking to control contamination at floor level include the use of standard flooring and regular disinfection; the use of tacky mats; or the layering of antimicrobial control mats made of polymeric materials.

The concern with standard flooring is that the disinfectants used to periodically treat the floor only have a short-lasting residual activity.

The activity of silver ions (Ag+) occurs as ions deposit themselves into the cell walls and vacuoles of bacteria and fungi, damaging cell structures

With tacky-mats, these are rarely of a sufficiently large surface area to effectively pull contamination from footwear, and they present a contamination control issue when each layer is removed in terms of resuspending a portion of the collected particles into the airstream.

Polymeric flooring has been shown to have a strong electrostatic charge and it can pull an equivalent (or better) levels of particles from footwear compared with the tacky mat (electrostatic forces are active across the optically flat, flexible surface, and this serves to pull away and to trap particles of varying sizes).

In addition, some manufacturers incorporate antimicrobial additives. In this case study, Dycem CleanZone flooring with Biomaster technology (providing silver ion activity) was tested.

Silver is a safe inorganic antimicrobial, effective at minute concentrations, exhibiting an ‘oligodynamic’ effect through the presence of toxic metal ions.

The activity of silver ions (Ag+) occurs as ions deposit themselves into the cell walls and vacuoles of bacteria and fungi, damaging cell structures.

Evaluating fungal remediation at floor level

To assess the effectiveness of antimicrobial polymeric flooring to reduce fungal numbers (as measured by colony forming units) a study was conducted at a pharmaceutical facility in the south-east of England.

This study evaluated Dycem CleanZone flooring located between a Controlled-Not-Classified (CNC) space leading into an EU GMP Grade C / ISO 14644 Class 8 (in operation) cleanroom changing area.

The study set out to demonstrate that shoe soles can be vectors for fungal contamination and to investigate if polymeric flooring is an effective decontamination device and hence decrease the risk of transferring fungal contamination into a cleanroom changing room effectively.

To test this, a diverse array of different types of fungal morphologies was required.

The following biohazard class I fungi were selected (as representatives of the environment, buildings and people): Aspergillus brasiliensis, Botrytis cinerea, Fusarium graminearum, Penicillium chrysogenum, Mucor circinelloides, and Candida albicans.

Each fungus was challenged, individually, onto standardised rubber-soled shoe soles

Each fungus was challenged, individually, onto standardised rubber-soled shoe soles. The shoes had previously been unworn and decontaminated with 6% hydrogen peroxide pre-use.

One shoe in each study was unspiked and this served as a negative control. The target challenge in each case was 10 to 100 colony forming units (CFU).

Each shoe challenge for each fungus was carried out three times (using different personnel).

The shoes were sampled before and after walking across flooring or from walking across the standard vinyl flooring.

An assessment of fungal survival on the sole of shoes under both test conditions was assessed.

Assessment of fungal counts was by contact plate

For the study, each person took six steps (each foot contacted the flooring three times equaling ‘three footsteps’) across both the CleanZone surface and the standard flooring.

Assessment of fungal counts was by contact plate, using Sabouraud Dextrose Agar (SDA), with each plate incubated at 20-25oC for 7 days (the optimal conditions for fungal growth).

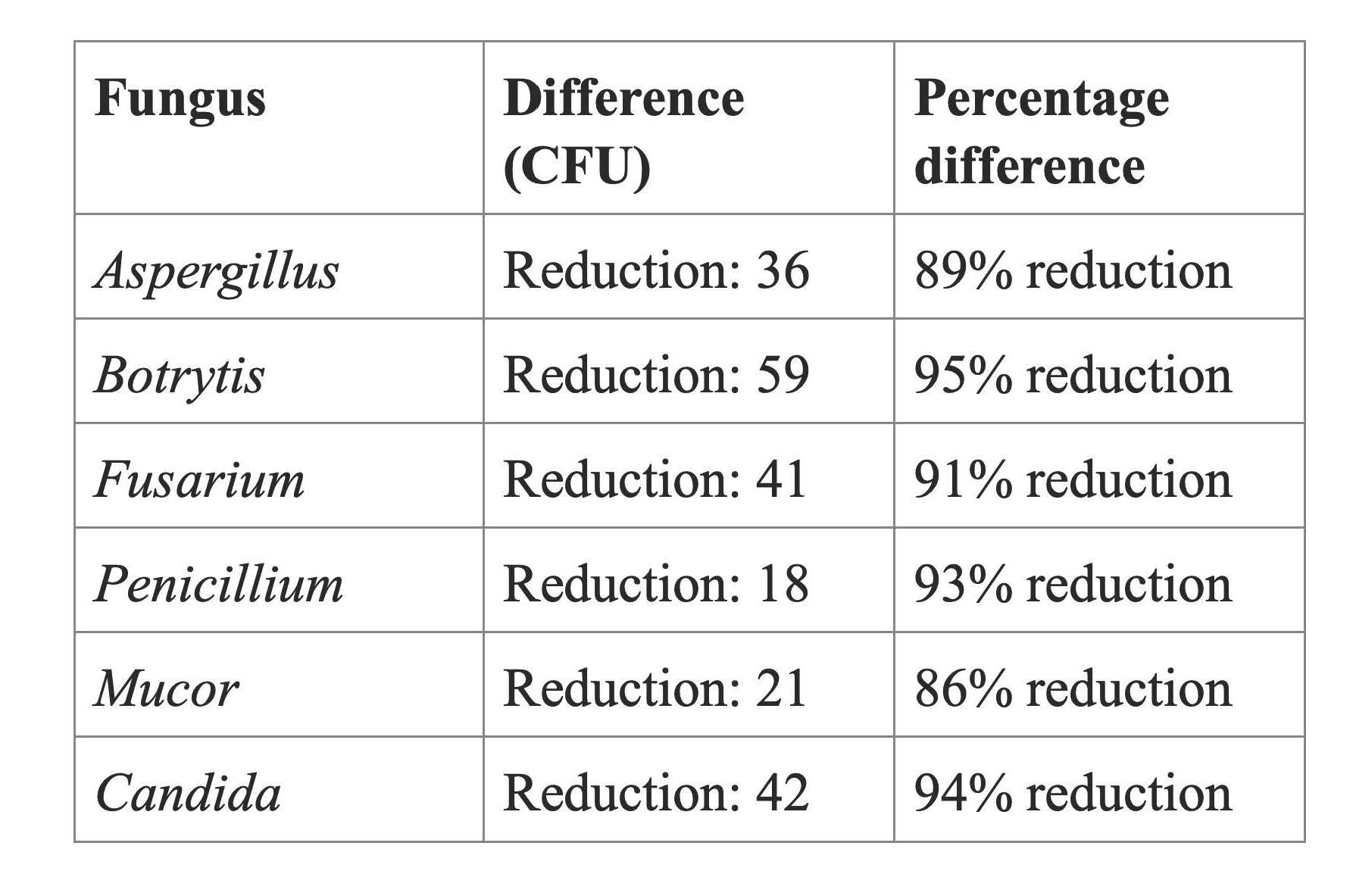

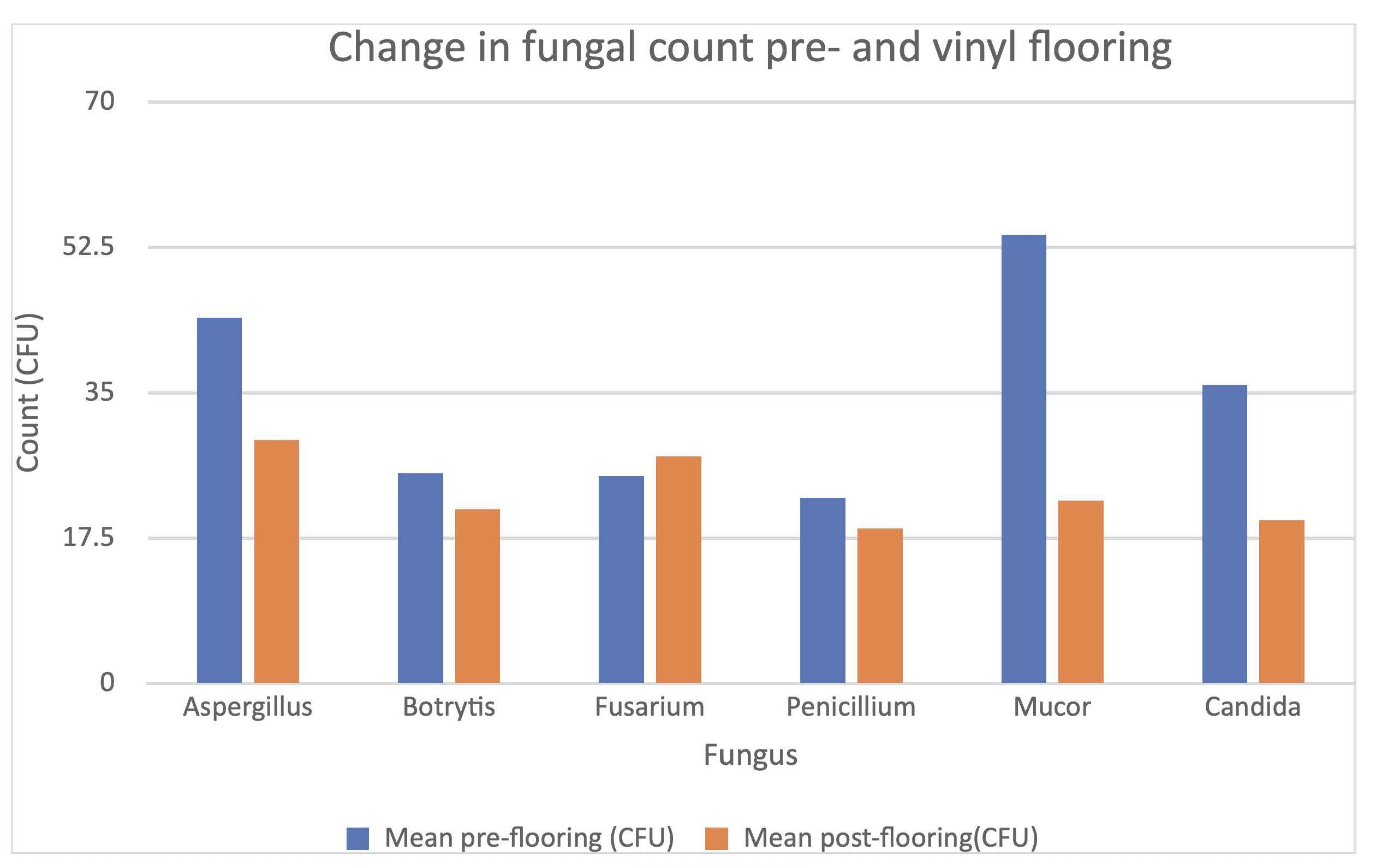

The results from the Dycem CleanZone assessment are shown in Figure 1 and Table 1.

Figure 1: Chart showing change in fungal counts after walking across the Dycem CleanZone flooring

Table 1: Changes in fungal count expressed as percentage change (in relation to Dycem CleanZone):

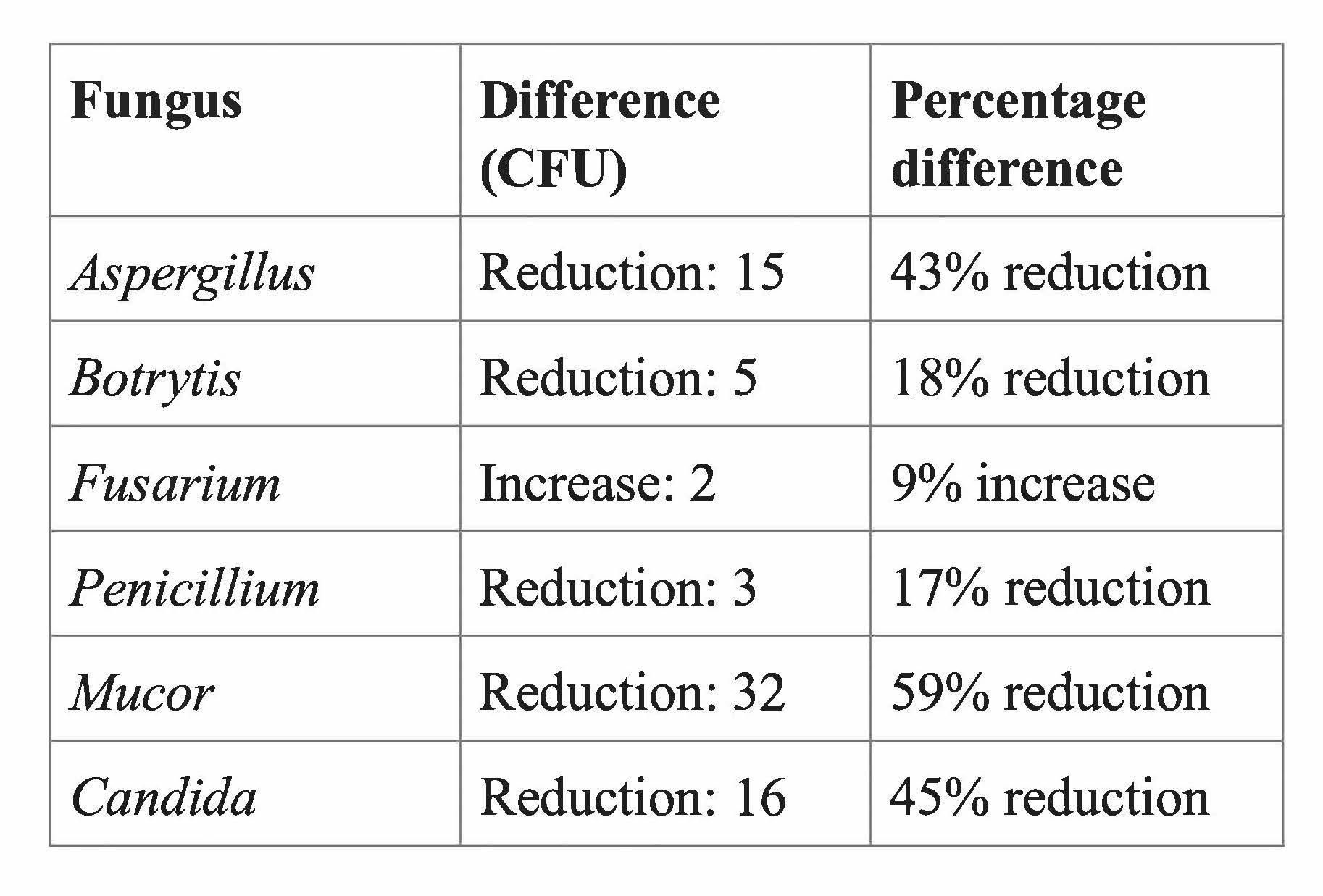

The results from the standard vinyl flooring assessment are shown in Figure 2 and Table 2.

Figure 2: Chart showing the change in fungal counts after walking across standard vinyl flooring.

Table 2: Changes in fungal count expressed as a percentage change (in relation to standard flooring).

Discussion

The results showed a clear difference in the levels of reduction seen between the Dycem flooring and the standard vinyl flooring.

The data shows that the Dycem CleanZone flooring reduced the fungal count significantly (a mean reduction of 91%, against 32% with standard flooring).

This will be the consequence of two mechanisms: the electrostatic nature of the flooring and the presence of silver ions.

The study can be broadened to other microorganisms

Furthermore, the results obtained against the Dycem flooring were relatively consistent, indicating that fungal diversity was a not a particular factor (unlike the standard flooring where reductions in count were relatively low for Botrytis and the levels marginally increased for Fusarium, albeit within standard error). Potentially the spores of certain fungi are difficult to detach from footwear.

There will be some variables that will influence the data relating to recovery error from the culture media and the different physiological states of the fungi.

However, given this error will apply to all samples, the significant difference between the two surfaces remains apparent.

The results obtained against the Dycem flooring were relatively consistent

Areas for further work include varying the length of time that the fungal challenge is in contact with the sole of the shoe; looking at different types of shoe and the age and any physical degradation of the shoe (where different physicochemical interactions between different fungi and the shoe surface could occur); considering differences between operators and the pressure applied when walking; and varying the number of footsteps taken.

In addition, the study can be broadened to other microorganisms.

Conclusion

The study presented in this article shows a clear advantage with the use of antimicrobial polymeric flooring (such as the Dycem range) compared with standard flooring as evaluated against a range of common fungi.

A microbial reduction step is apparent both in terms of the pulling away of particles from shoes and as a consequence of ionic activity.

On this basis, such flooring can contribute towards a facility contamination control strategy and to support other contamination reduction measures including cleanroom air control, personnel gowning, and regular cleaning and disinfection.