Despite the 2006 ATEX directives, many companies still fail to ensure the safe running of motors and low voltage AC drives in dusty areas, argues ABB.

The ATEX directives, introduced in 2006, were aimed at facilities handling dusty or potentially flammable materials, but many companies still fail to ensure the safe running of motors and low voltage AC drives. Dusty environments where powdered ingredients are being handled can be just as hazardous as atmospheres with flammable gas. So the use of electric motors and low voltage AC drives in areas with combustible dust is regulated by the ATmosphere EXplosive (ATEX) directives. In particular, ATEX directives 95 and 137 aim to ensure that only equipment with specific safety features is used in areas that could, potentially, contain flammable atmospheres.

Throughout pharmaceutical manufacturing plants there are hundreds of electric motors and low voltage AC drives used for process equipment and compressed air systems, to operate HVAC systems, to drive laboratory or bulk manufacturing equipment, including mixers, pumps, centrifuges and dryers, and to move and operate filling and finishing equipment. More than 80% of the electricity consumed in pharmaceutical manufacturing is used to power motors that stir, agitate, compress, and pump liquids around the plant. And even the most unlikely everyday materials that are being handled by these motors have the potential of causing an explosive atmosphere.

Low voltage AC drives used with electric motors can offer significant process improvements and energy savings for pumps, fans and other equipment used in pharmaceutical facilities, and there are several ways to secure safe running of motors and low voltage AC drives in dusty environments.

As with most equipment, one of the biggest risks is the accidental ingress of metallic foreign bodies that can cause sparks directly or indirectly by causing moving machinery to fail in some way. Thus, it is imperative that operators take every precaution to ensure that such objects cannot enter equipment that would be put at risk.

Combustible dust is an insidious hazard. Sometimes its presence may even be known, but ignored because we don't think of some ordinary substances as being hazardous materials. However, when reduced to dust, such materials have a very large surface area and can burn extremely rapidly, causing an explosion with very high energy. The main reason that dust hazards are frequently overlooked is a simple lack of understanding about the materials. Many materials can form combustible dust including some chemicals and pharmaceuticals and even metals, e.g., aluminum and aluminum alloys.

>p>Preventing accidentsLike all explosions, dust explosions require fuel, oxygen and an ignition source to get started. In addition, dust explosions need two more components, dispersion and confinement. Dispersed in the air, dust can create a rapidly burning fireball. When the dust is confined inside a building or a piece of equipment, a powerful explosion can occur and propagate. A dust fire can have devastating effect. In addition to injuries and loss of life, it can destroy a plant as the explosions rip through ducting and ceiling voids. Yet, dust fires are completely preventable.

Since 2006, areas with dust come under the ATEX regulations that control installations in hazardous areas and they are classified in the same way as hazardous areas with gas and equipment is selected on the same basis.There are two legs to the ATEX regulations: ATEX 95 controls product safety while ATEX 137 is the worker protection directive. Safe operation of the equipment is the result of cooperation between the manufacturer, the end-user and, if used, the contractor. However, responsibility for explosion protection can never be contracted out to a third party. The manufacturer is responsible for the equipment being safe when it leaves the factory. The end-user is responsible for ensuring that the product is installed, maintained and operated so that it does not pose a danger of explosion. The end-user must also define the Zone, temperature and preferred protection class. Based on this, the manufacturer proposes the equipment to be used.

ATEX 95 gives the safety requirements for equipment capable of causing an explosion through its own potential sources of ignition. The directive guides manufacturers to prepare classifications of equipment as well as instructions for installation and use, and to certify the equipment and its production.

The worker protection directive ATEX 137 covers minimum requirements for improving health and safety protection of workers operating in potentially explosive atmospheres. The directive requires a consistent assessment of all measures to prevent risks of explosions and injury to people inside and outside the plant.

Zones and categories

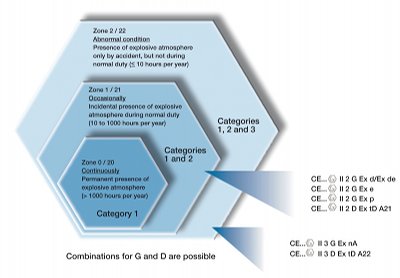

Hazardous areas are classified in Zones based on the frequency and the duration of occurrence of an explosive atmosphere. Areas where explosive atmosphere with dust is present continuously, for long periods or frequently due to malfunctions are classified as Zone 20; this corresponds to Zone 0 for hazardous atmospheres with gas. Areas where explosive atmosphere is likely to occur due to expected malfunctions in normal operation are classified as Zone 21, corresponding to Zone 1 for gas. Areas where explosive atmosphere with dust is unlikely to occur or, if it does occur, is likely to be of short duration and not in normal duty, are classified as Zone 22, corresponding to Zone 2 for hazardous atmospheres with gas.

Equipment is arranged into Categories. The notion of Zones does not exist in the product directive, ATEX 95; the Zones are instead defined in the end-user directive, ATEX 137. The Zone indicates which Category of equipment needs to be used. It is the end-user's duty to select the right product for the right Zone - equipment of Category 1 for Zone 0 or 20; equipment of Category 1 or 2 for Zone 1 or 21; and equipment of Category 1, 2 or 3 for Zone 2 or 22.

Motors for areas with hazardous dust are known as Ex tD motors, which are split into two Categories, Category 2D for Zone 21 and Category 3D for Zone 22; no motors can be used in Zone 20 or Zone 0.

Category 2 motors must be certified by a Notified Body, but for Category 3 motors, self-declaration of conformity by the motor manufacturer, based on internal quality control, is sufficient. However, as the additional cost for independent certification is fairly small, motor manufacturer ABB has chosen to also have its Category 3 motors certified by a Notified Body.

Motors and low voltage AC drives

Ex tD motors are used in atmospheres where explosive dust surrounds the motor, or where dust settles under its own weight on the motor. Dust is measured either as a cloud of dust or a layer of dust. The ignition temperatures for various types of dust can be obtained from commercially available reference tables. The ignition temperature for a cloud of dust must be at least 50% above the motor's marking temperature. The ignition temperature of a 5mm layer of dust must be 75°C above the marking temperature of the motor. It is the responsibility of the user to stage maintenance periods so that the dust layer does not build up above 5mm.

Motors with low voltage AC drives can be installed in hazardous areas, offering safe, economical power combined with effective control. However, the drive must always be installed in a safe area and it is important to recognize the effects the drive has on the motor, mainly to prevent motor surface over-temperature. The motor temperature can be controlled by using a temperature measurement signal from the motor and use this signal to initiate shut-down at high temperature. Alternatively, it is possible to monitor the amount of energy transferred to the motor and control the temperature this way; the energy flow can be easily monitored if using an ABB industrial low voltage AC drive with the motor control platform DTC (direct torque control). Otherwise, a combined test with the motor and low voltage AC drive is necessary to ensure that the motor surface temperature does not exceed the limits. It is also possible to purchase an ATEX approved package with motor and low voltage AC drive.

The permitted equipment categories

End-user responsibilities

The ATEX regulations requires users to draw up an Explosion Protection Document to decide whether hazardous area motors are needed, assessing each area of the plant for hazardous gas or dust and dividing the plant into zones. An area can be declared safe only as the result of a risk assessment. Once the plant is correctly divided into zones, the appropriate equipment for each zone can be selected.

Although the ATEX directives are only applicable within the EU, they are based on European standards which have lead to their principles being demanded by users throughout the world. However, ATEX approval is generally not recognized outside Europe and industries with hazardous areas should investigate which approval schemes apply locally.

The Zone system is used worldwide, except in the US, where a system of Classes and Divisions is used to denote hazardous locations. The Classes are based on the type of hazard and the Divisions on the risk of explosion that the material poses. However, some US manufacturers have started referring to Zones to enable them to sell equipment to end-users in the EU.

It may be tempting to try and simplify the risk assessment by using a blanket zone to cover the entire site but this could be a mistake. More expensive, over-protected equipment will have to be bought, installed and inspected. The use of over-specified equipment can have long-term financial implications, as the maintenance and repair obligations under ATEX depend on the Category of equipment, not the Zone it is installed in. Blanket zoning also raises a suspicion that the risk analysis may not have been carried out in sufficient detail.

Although the ATEX directives have been in force since 2006, many companies still seem unaware of their obligations and of the dangers posed by combustible dust. As the law now requires companies to work with prevention, industrial disasters caused by combustible dust explosions should hopefully become a thing of the past.