When working with biosafety cabinets we expect protection for personnel, environment, samples and public health. If our biosafety cabinet fail in one of these points, we can compromise: the people who are working in the laboratory, the quality of our work and consequently the public's health.

All class 2 biosafety cabinets are defined as partial barriers where the protection depends on the airflow balance and filter integrity.

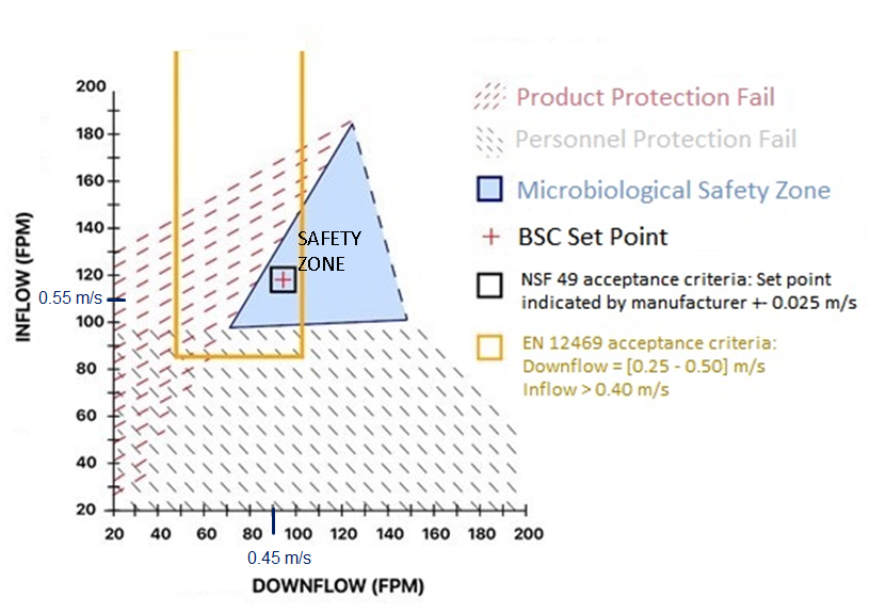

The airflow that is captured by the front grille is called the inflow. If it is very high samples will be contaminated. If it is very slow, the user can get contaminated.

The integrity of the HEPA filters is tested using the aerosol photometer method to meet the current testing standards

The downflow air is a uniform airflow that descends from the top of the workspace to the work surface and is distributed between the front and rear grills. This internal airflow minimises the risk of cross-contamination. If it is very high you could compromise the inflow velocity and you may have a turbulent flow. If it is very slow it cannot reach the right velocity to move the aerosols.

All the set points are defined by the manufacturer and based on microbiological testing.

The integrity of the HEPA filters is tested using the aerosol photometer method to meet the current testing standards. The objective is to find leaks in the filters and the filter seal.

So, what does the definition of biosafety cabinets tell us?

It tells us, that biocontainment depends on the inflow and downflow velocity and the integrity of filters.

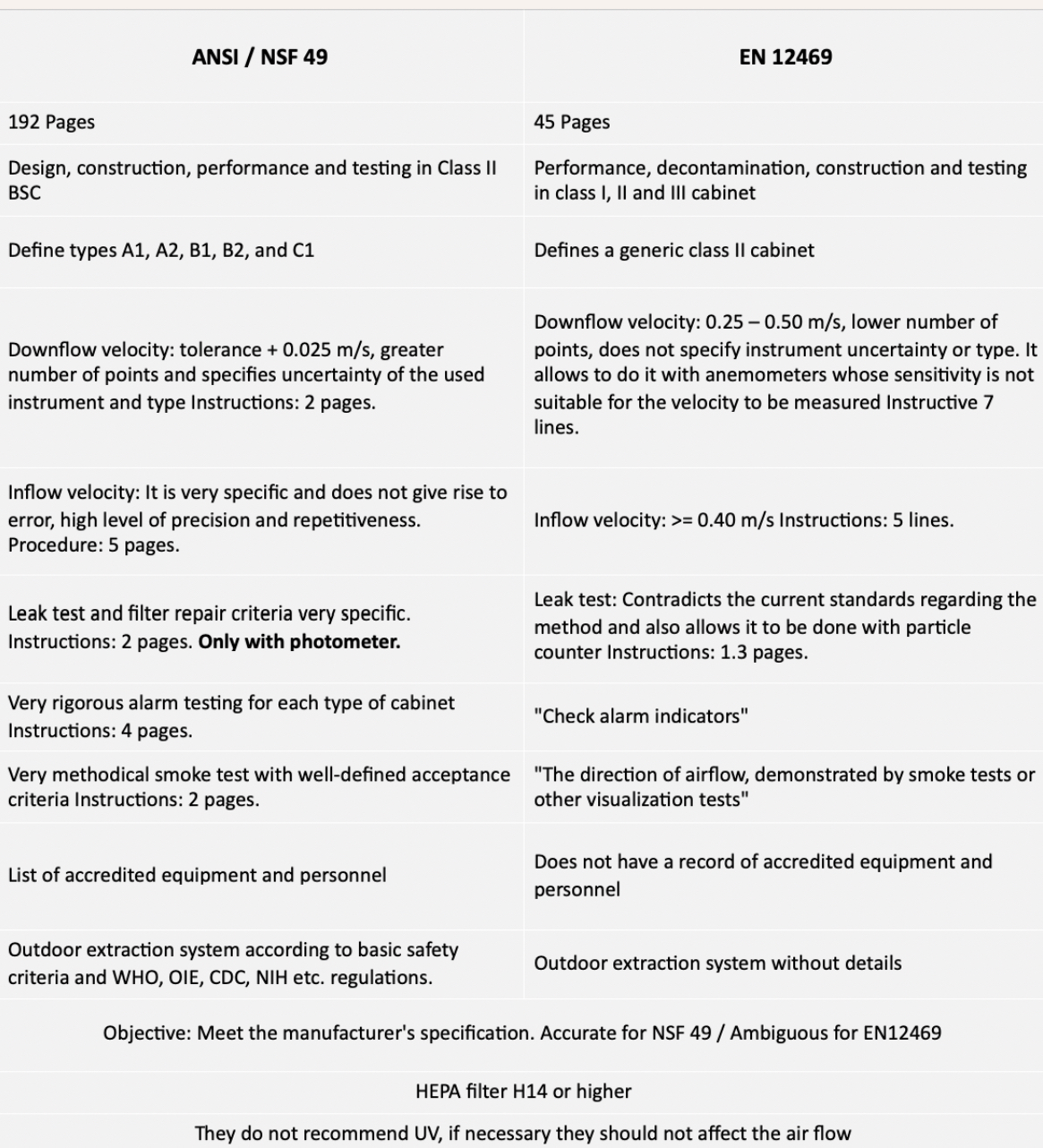

Worldwide, the most cited standard for building and performing annual field certification is ANSI/NSF 49, followed by EN 12469. Next, we will analyse technically both standards when it comes to field certification.

When comparing the texts of EN 12469 with older texts of NSF 49, it is found that the standard was based on the text of the NSF 49:1992 version. But also that it has been truncated by removing a lot of important information and especially the disambiguations that clarify the correct way to carry out the tests.

Technical differences

NSF has 192 pages that include Design, construction, decontamination, performance and testing in Class II BSC and defines the known A1, A2, B1, B2 and C1 biosafety cabinet types. This is very important because, for example, if you are testing a BSC type B2 under EN, B2 is not defined in this standard, so as not defined by A1, A2 or C1. What we see in EN is a generic cabinet similar to A2, but not defined as A2.

EN has 45 pages that include performance, decontamination, construction and testing in class I, II and III BSC. All the information is too short and incomplete.

Downflow velocity

Downflow velocity is the speed at which the airflow descends from the top of the work surface.

NSF 49 defines as acceptable downflow velocity value the set point value indicated by the manufacturer with a tolerance +- 0.025 m/s (-+5 FPM), measured with a hot wire anemometer and with an accuracy of 0.015 m/s.

A strict technique must be applied to define the measurement grid. On the other hand, the EN 12469 standard indicates as acceptable the values between (0.25 - 0.50) m/s or (50 - 100) FPM regardless of dimensions, aerodynamic conditions, etc. And it allows to perform with other types of anemometers without indicating the accuracy of the instrument. EN 12469 does not indicate a method or technique for marking the measurement grid.

Inflow velocity

Inflow velocity is the speed at which the airflow gets into the front grills and protects the user from the risk inside the work space and protects the samples from being contaminated by the laboratory air.

NSF 49 describes over 5 pages the different approved methods to establish and calculate the inflow velocity value, while the EN 12469 standard in only 5 lines, without specifying measurement techniques or where the measurements should be taken, indicates that this speed must be at least 0.40 m/s (80 FPM).

HEPA/ULPA filter leak testing

Leak testing is one of the most important tests in a biosafety cabinet, because the HEPA/ULPA filters are a biological barrier. If there is leakage, there is contamination.

The NSF 49 leak testing is the photometer method. It is very specific about how to measure the upstream aerosol concentration and how to take the downstream concentration to have the aerosol penetration rate and conclude if the filter has a leak or not. NSF does not allow the HEPA/ULPA filter leak test with particle counter.

Instead, in EN the instruction contradicts the current standards regarding the method and allows it to be done with a particle counter, but this is not according to the method expressed in ISO 14644-3 or the technical guide for leak testing in HEPA filter IEST 34.

There is no technical, scientific, or human-responsible reason to not use the photometer method listed in NSF 49.

Alarm testing

NSF is very rigorous on the alarm testing, as it has four pages of testing instructions, and the checklist is different between A2, B1, B2 and C1 types of BSC… while EN only reads “Check alarm indicators”.

Smoke test

NSF has a very methodical smoke test, and well-defined acceptance criteria, so it consists of 2 pages of a complete methodical procedure, to find problems with the airflow, that couldn’t be detected in the airflow test… while EN only states “The direction of airflow, will be demonstrated by smoke tests or other visualization tests".

Outdoor extraction

NSF follows the biosafety criteria in the biosafety literature like OMS Laboratory Biosafety Manual or BMBL 6th. This is basically the obligation of use and testing of canopy connection in A1 and A2 cabinets. The Canopy Connection is a system that works as an air shock absorber, if the flow of air extracted in a forced way from the outside, is reduced or blocked, the cabin type A does not lose its inflow velocity and sounds an alarm indicating that the extraction to the outside has been lost, avoiding putting the user at risk. In B1 and B2 cabinets NSF allows direct connection but interlocks and alarms shall be tested.

But EN doesn’t have any details, about how should be done, and allows direct connections, under EN 12469 an A2 cabinet may have a direct connection instead of a canopy connection, putting in risk the user and the environment without user acknowledgment.

Why do we prefer the NSF 49 to the EN 12469?

- The precision of the methods.

- Well-founded tolerances.

- Repeatability of the results.

Conclusions

Using EN 12469 it is very common to conclude that the cabinet is in good condition to be used, but the contamination could be going outside of the workspace or contamination of the air laboratory could be getting inside the workspace, and the leak testing in the HEPA/ULPA filters could have been performed in such way that no leak detection is possible. That is why it is so common to see KI-Discus tests fail in cabinets that meet EN12469 annual tests.

The goal of the biosafety cabinet certification is to verify that the critical parameters that impact directly on the workers, environment, samples and public health, are compiled to the manufacturer's specifications.

Using NSF 49 instead EN 12469 we can be sure of meeting the objective.